Automated Sampling of Methanol Extractions

EST Analytical: Automated Sampling of Methanol Extractions

Abstract

The United States Environmental Protection Agency (USEPA) Method 8260 is used in order to ascertain volatile organic compounds in waters, soils and solid waste samples. Often times, soil and solid waste samples are so highly contaminated the sample needs to be dispersed in methanol. Sample collection for contaminated soils can be obtained in two ways. One, dispersing a bulk soil sample into a 40ml vial and adding methanol in the lab or two, sending preweighed vials with a septum sealed cap that already contains the pre-requisite methanol out in the field for soil sampling. No matter how the soil sample is dispersed in methanol, an aliquot of the methanol extract needs to be added to water and purged using USEPA Method 5030. This application will investigate automated sampling of methanol soil extractions.

Introduction: Environmental labs are required to perform methanol extractions on highly contaminated solid waste samples. Additionally, these extractions are used for difficult matrices, for example oily waste samples, that are also soluble in methanol. Due to the variety of matrices that can be extracted with methanol there are assorted hurdles to cross in order to automate the sampling process. One of these obstacles is how the matrix can absorb the extraction solvent. For example, many soil samples require more methanol; due to the soil expanding with the solvent addition. Adding more methanol aids in rectifying this issue however, when automating sampling, the added methanol coupled with the soil expansion needs to be accommodated. For this reason, EST Analytical created software for the Centurion WS that allows the user to program the needle depth to different distances. In doing this, laboratories are able to sample soils at higher depths in order to adjust for sample absorption and at lower depths for samples that do not require the added solvent. In order to test volatile compounds in methanol extractions, a portion of the extract needs to be sampled from the vial, diluted, and purged on a purge and trap concentrator. This examination will look at the automated sampling of three different soil matrices.

Experimental

The Centurion WS autosampler with the syringe option and the Evolution purge and trap concentrator were set up to run methanol extractions. Since this is a volatile analysis, a Vocarb 3000 (K) trap was used for the analytical trap. The sampling system was configured to an Agilent 7890A Gas Chromatograph (GC) and an Agilent 5975C inert XL Mass Spectrometer (MS). The column selected for this analysis was a Restek Rxi®-624 Sil MS, with dimensions of 30m x 0.25mm I.D. x 1.4µm film thickness. Experimental parameters used for this analysis are listed below.

Purge and Trap Parameters

- Concentrator: EST Encon Evolution

- Trap type: Vocarb 3000

- Valve oven temperature: 150 °C

- Transfer line temperature: 150 °C

- Trap temperature: 35 °C

- Moisture Reduction Trap (MoRT) temperature: 39 °C

- Purge time: 11 min

- Purge flow: 40 mL/min

- Dry purge Temp.: Ambient

- Dry Purge Flow: 40mL/min

- Dry Purge Time: 1.0 min

- Desorb pressure Control: ON

- Desorb Pressure: 6psi

- Desorb time: 0.5 min

- Desorb preheat delay: 15 sec

- Desorb temperature: 260 °C

- MoRT bake temperature: 210 °C

- Bake temperature: 270 °C

- Sparge vessel bake temperature: 120 °C

- Bake time: 8 min

- Bake flow: 85 mL/min

Purge and Trap Auto-Sampler: EST Centurion WS

- Sample Type: Water

- Water Volume: 5ml

- Sample Prime Time: 5 sec

- Loop Equilibration Time: 5 sec

- Sample Transfer Time: 15 sec.

- Syringe Rinse: On/6 ml

- Number of Syringe Rinses: 2

- Sample Loop Rinse: On/15 sec

- Sample Sweep Time: 15 sec

- Number of Sparge Rinses: On/2

- Rinse Volume: 5 ml

- Rinse Transfer Time: 15 sec

- Rinse Drain Time: 25 sec

- Internal Standard Vol.: 5 µl

- Extraction: MeOH Prep A (Sand and Clay)

- Extraction: MeOH Prep B (Potting Soil)

GC/MS Parameters

- System: Agilent 7890/5975

- Inlet: Split/splitless mode, 220 °C, 40:1 split ratio, 12.153 psi inlet head pressure

- Column: Rxi-624Sil MS 30m x 0.25mm I.D. 1.4µm film thickness

- Oven program: 45 °C (1 min) → ramp 15 °C/min → 220 °C, hold for 1.33 min, 14 min run time

- Column flow rate: 1 mL/min helium

- Total flow: 44.0 mL/min

- Source temperature: 230 °C

- Quadrupole temperature: 150 °C

- Transfer line temperature: 180 °C

- Scan range: m/z 35–300, 5.2 scans/sec

- Solvent delay: 0.7 min

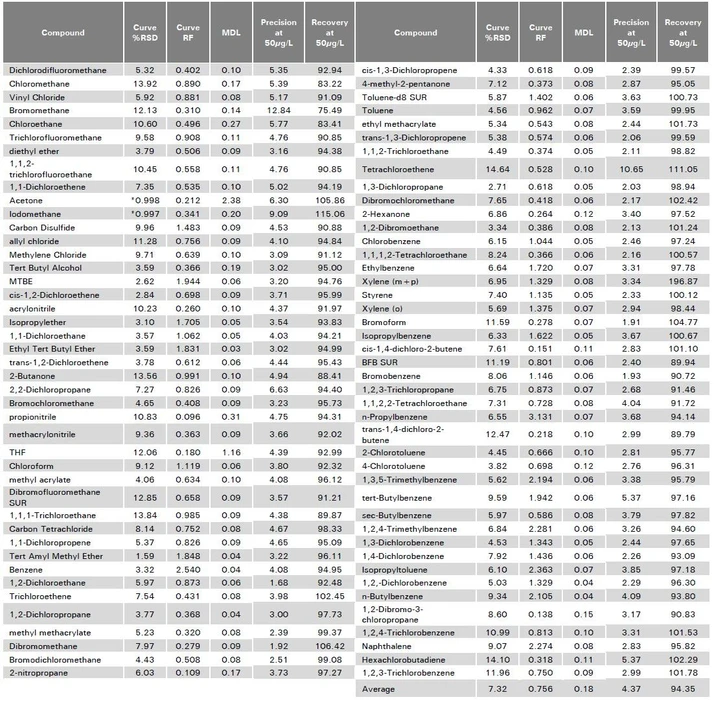

The EPA method 8260 standards were acquired from Restek while the purge and trap grade methanol was procured from JTBaker. A nine point methanol curve was established from 0.5 to 200µg/L. Next Method Detection Limits (MDLs) were found running seven replicates of the low point on the curve. Precision and accuracy was determined by examining seven replicates of the 50µg/L standard. Table 3 displays the curve, MDL and precision and accuracy results. A set of three spiked sand matrix samples were used to establish the accuracy of the automated extraction at a 50µg/L concentration, see Table 4.

EST Analytical: Table 3 - Curve, MDL and Precision and Accuracy Results.

EST Analytical: Table 3 - Curve, MDL and Precision and Accuracy Results.

EST Analytical: Table 4 - Results of Automated Extraction of a Sand Matrix

EST Analytical: Table 4 - Results of Automated Extraction of a Sand Matrix

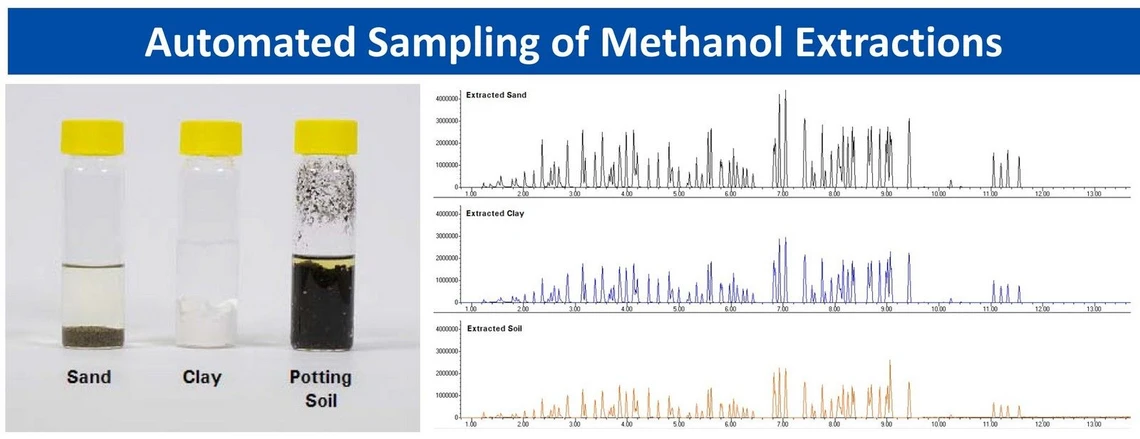

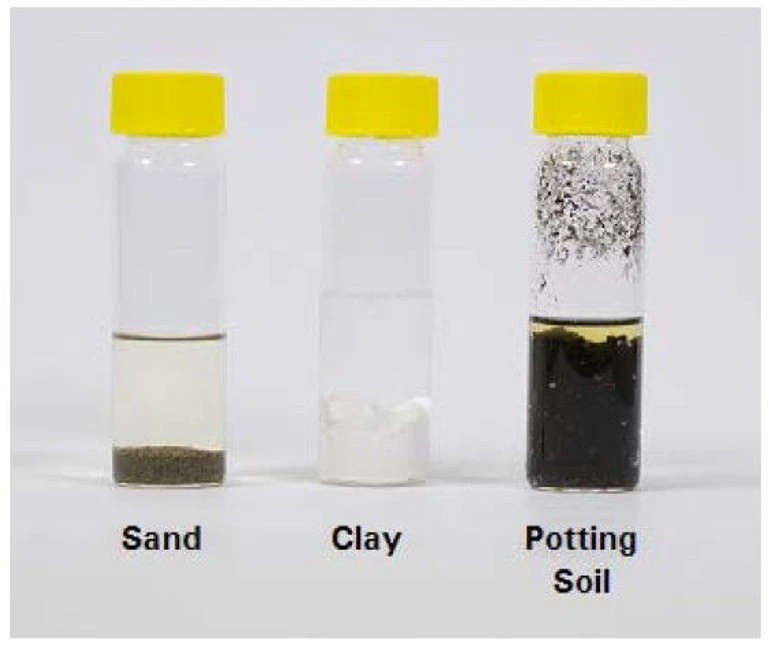

Finally, sand, clay and soil matrices were extracted in order to compare the chromatography of the automated extractions using different matrices. The matrix comparison required 5 grams of soil and 15mls of methanol due to the potting soils’ absorption of the methanol. Thus, in order to make a direct comparison, all of the matrices were spiked with the same volume of standard and extracted with 15mls of methanol. Figure 1 displays a comparison of the three matrices and their respective interaction with the extraction solvent and Figure 2 shows the chromatograms of the three matrices.

EST Analytical: Figure 1 - Image of 5g of soil matrices in 15mls of Methanol

EST Analytical: Figure 1 - Image of 5g of soil matrices in 15mls of Methanol

EST Analytical: Figure 2 - Chromatograms of Automated Extraction of Sand, Clay and Soil

EST Analytical: Figure 2 - Chromatograms of Automated Extraction of Sand, Clay and Soil

Conclusions

The system produced excellent results. The curve and the compound response factors met all of the method requirements. The overall precision was less than 5% RSD while the system showed an average recovery of 94%. When examining the expected analyte concentration to the extracted sand results, it was found that the average recovery was approximately 102%. Thus, the automated extraction performed extremely well. When comparing the three different matrices it was found that they all displayed similar recoveries, however the sand matrix did perform the best of the three as expected since sand tends not to absorb analytes as readily as other matrices. Finally, the ability to control the needle depth on extraction samples was a great benefit for the different matrices as the system exhibited no issues with needle clogging due to the higher needle depth when performing the potting soil extractions. As demonstrated from this study, the Centurion WS automated extraction capability would be an asset to any lab performing extractions.

- Volatile Organic Compounds by Gas Chromatography/Mass Spectrometry (GC/MS); United States Environmental Protection Agency Method 8260B, Revision 2, December 1996.

- Closed System Purge and Trap and Extraction for Volatile Organics in Soil and Waste Samples; United States Environmental Protection Agency Method 5035, Revision 0, 1996.