Flavor Compound Abundances in Orange Juice Comparison Using Purge and Trap

EST Analytical: Flavor Compound Abundances in Orange Juice Comparison Using Purge and Trap

Abstract

Before the advent of orange juice from concentrate, people would fresh squeeze oranges for their juice. Concentrate helped make orange juice easier to make and increased its popularity. Following concentrate, manufacturers used flash pasteurization and created ready to drink orange juice and again sales increased. Due to disease in the orange groves and the possibility of the crops getting destroyed by frost, the production of orange juice has gotten more expensive. The increase in production costs creates competition within the orange juice industry to create an orange juice that the public will enjoy and increase their consumption. This application will look at the flavor compound abundances of three different brands of orange juice using purge and trap concentration.

Introduction

Pasteurization is the first step in the creation of commercial orange juice. This is required in order to kill any harmful bacteria in the juice before it is sold. After the juice is pasteurized, it can be sold. However, since different orange varieties are in season at different times, most juice is squeezed and stored. The storage times vary and with storage there can be other issues. One of these issues is oxidation. Thus, many companies remove the oxygen from the juice before they store it. Between pasteurization and oxygen removal, the juice will lose some of its flavor. This is where juice manufacturers can differentiate themselves.

Flavor compounds and amounts can make a substantial difference in the overall taste, acidity and odor of the juice. So, to create a juice that the public wants to buy, it is essential that the analysis of the flavor compounds and the percentage of these flavors be accounted for. Purge and trap is an excellent technique for the extraction of volatile flavor compounds within a liquid matrix. This is an exhaustive technique and generates reproducible results. This application will compare the reproducibility and ratios of flavor compounds in orange juice using the EST Analytical Evolution purge and trap concentrator.

Experimental

The EST Analytical Evolution purge and trap concentrator was set up with a Vocarb™ 3000 trap while the Centurion WS autosampler was set to run in soil mode. The sampling system was configured to an Agilent 7890A Gas Chromatograph (GC) and 5975C inert XL Mass Spectrometer (MS) for separation and analysis. As the compounds of interest for this analysis were volatile, a Restek Rxi® 624 Sil MS 30m X 0.25mm X 1.4µm column was affixed in the GC. Sampling and analysis parameters were optimized and are listed below.

Purge and Trap Parameters

- Concentrator: EST Encon Evolution

- Trap type: Vocarb 3000

- Valve oven temperature: 150 °C

- Transfer line temperature: 150 °C

- Trap temperature: 35 °C

- Moisture Reduction Trap (MoRT) temperature: 39 °C

- Purge time: 11 min

- Purge flow: 40 mL/min

- Dry purge Temp.: Ambient

- Dry Purge Flow: 40mL/min

- Dry Purge Time: 1.0 min

- Desorb pressure Control: ON

- Desorb Pressure: 6psi

- Desorb time: 0.5 min

- Desorb preheat delay: 5 sec

- Desorb temperature: 260 °C

- MoRT bake temperature: 210 °C

- Bake temperature: 270 °C

- Sparge vessel bake temperature: 120 °C

- Bake time: 8 min

- Bake flow: 85 mL/min

Auto-Sampler (EST Centurion WS):

- Sample type: Soil

- Sample Fill Mode: Syringe

- Water Heater Temp.: 85°C

- Sample Preheat Time: 0.5min

- Sample Preheat Temp.: 40°C

- Soil Valve Temp.: 85°C

- Soil Transfer Line Temp.: 150°C

- Minimizer Time: 2 min

GC/MS Parameters

- System: Agilent 7890/5975C

- Inlet: Split mode, 220 °C, 40:1 split ratio, 12.153 psi head pressure

- Liner: Restek Split liner, 1mm x 6.3 x 78.5

- Column: Restek Rxi-624Sil MS, 30 m × 0.25 mm × 1.4 µm

- Oven program: 45 °C (1 min) → ramp 15 °C/min → 300 °C, hold 5.00 min (total run ~23 min)

- Column flow rate: 1 mL/min helium

- Total flow: 44 mL/min

- Source temperature: 230 °C

- Quadrupole temperature: 150 °C

- Transfer line temperature: 180 °C

- Scan range: m/z 30–350, 4.4 scans/sec

- Solvent delay: 0.7 min

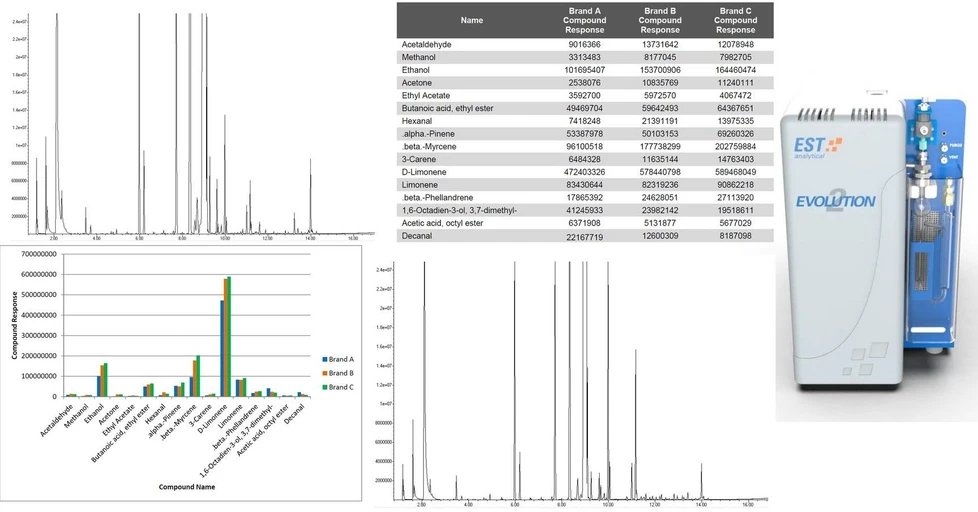

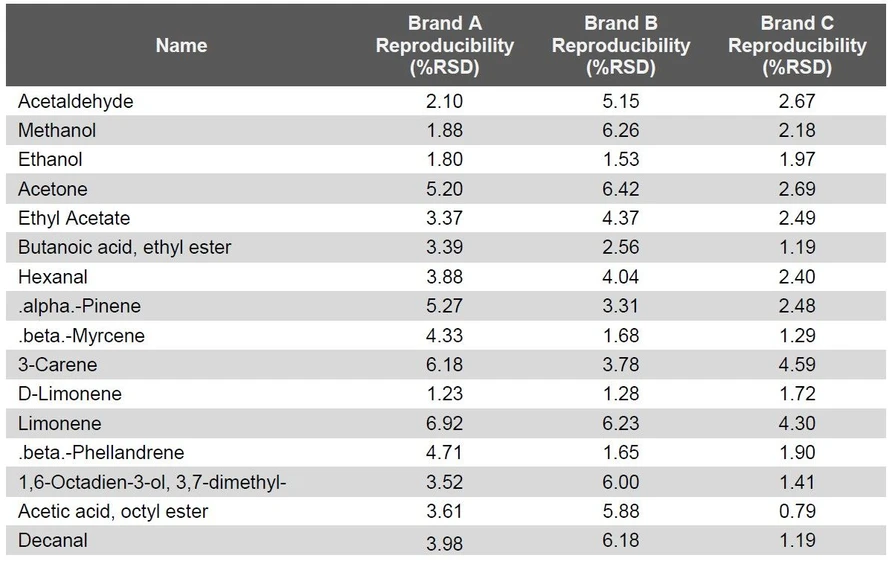

Three different orange juice brands were purchased at the local market. Ten milliliters of each orange juice was measured and placed in a 40ml vial. Each vial was then deposited in the Centurion WS autosampler to be purged in soil mode and concentrated on a Vocarb 3000 trap in the Evolution concentrator. Finally, the samples were in run in triplicate in order to ensure the reproducibility of the results. Agilent MassHunter Qualitative Analysis software was used for the determination of the flavor compounds in the juice samples. Table 1 displays the reproducibility of the sampling process whereas Table 2 lists a comparison of the flavor compound abundances.

EST Analytical: Table 1 Reproducibility of the Results

EST Analytical: Table 1 Reproducibility of the Results

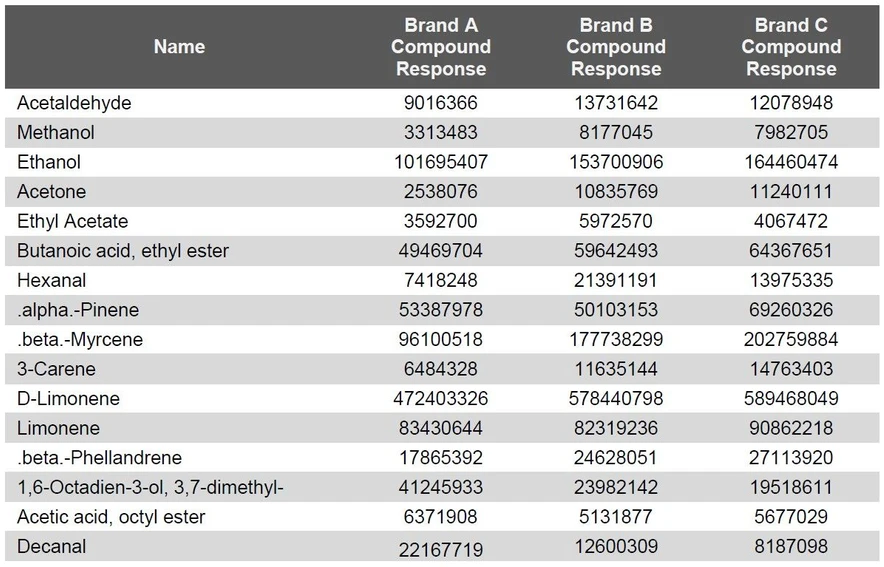

EST Analytical: Table 2 Flavor Compound Abundance Summary

EST Analytical: Table 2 Flavor Compound Abundance Summary

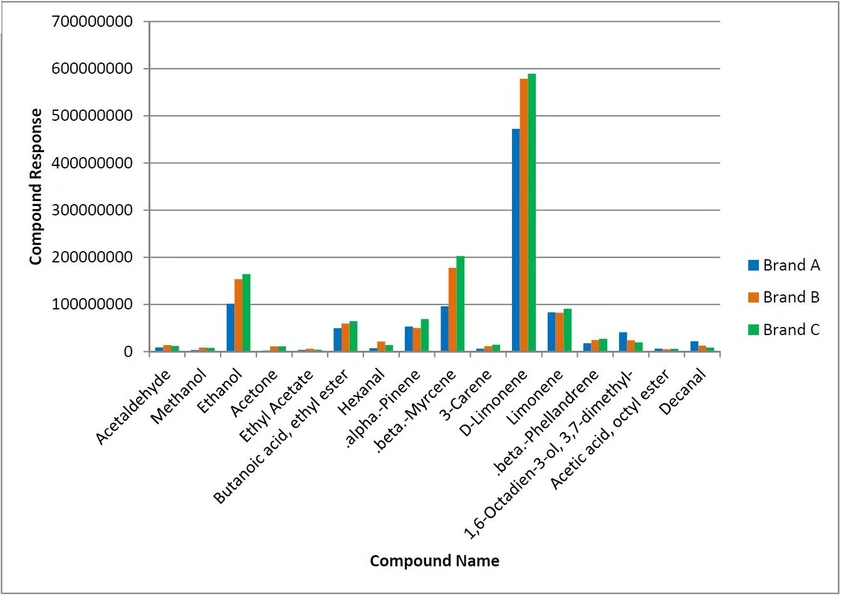

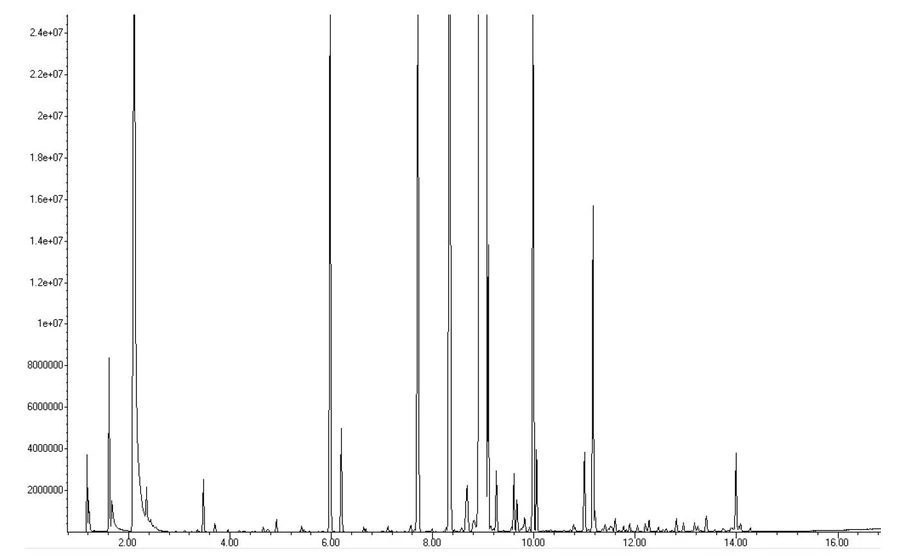

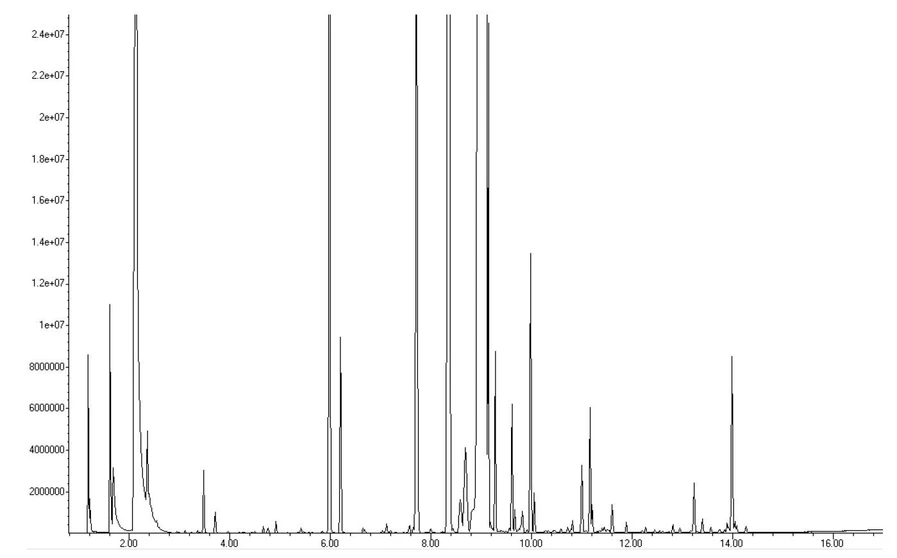

Figure 1 is a bar graph comparison of the compounds in the three juice brands while Figures 2, 3 and 4 are the respective chromatograms of the juice samples.

EST Analytical: Figure 1 Bar Graph Compound Abundance Comparison

EST Analytical: Figure 1 Bar Graph Compound Abundance Comparison

EST Analytical: Figure 2 Brand A Chromatogram

EST Analytical: Figure 2 Brand A Chromatogram

EST Analytical: Figure 3 Brand B Chromatogram

EST Analytical: Figure 3 Brand B Chromatogram

EST Analytical: Figure 4 Brand C Chromatogram

EST Analytical: Figure 4 Brand C Chromatogram

Conclusions

Using the EST Analytical Evolution purge and trap concentrator coupled to the Centurion WS autosampler to evaluate flavor compounds in orange juice samples proved to be a reliable sampling technique. The results were reproducible and the chromatography was excellent. The three different orange juice brands had very similar chromatograms; however upon further analysis many subtle differences in the abundances of the flavor compounds could be discerned. Traditionally, headspace and solid phase micro extraction sampling are used for this type of analysis. However, the purge and trap sampling technique used for this examination offered an excellent alternative for the determination of the volatile components in a juice matrix.