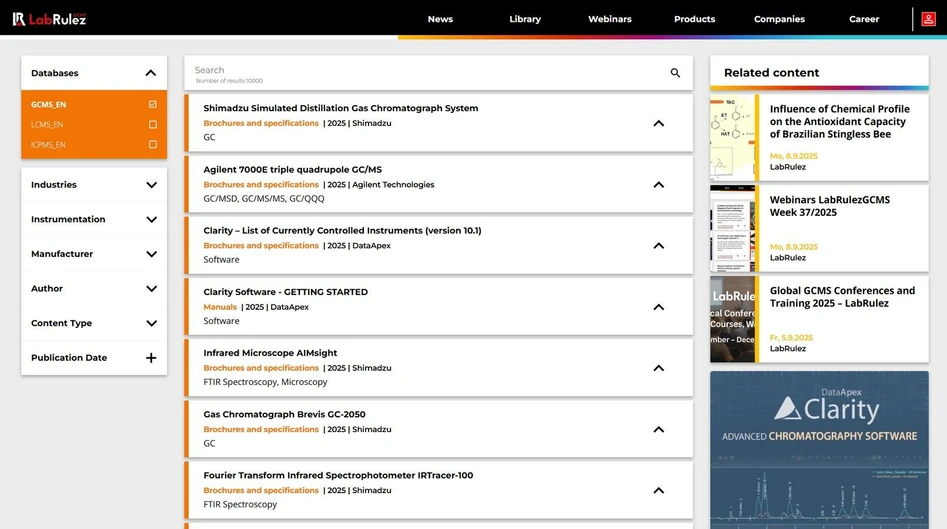

News from LabRulezGCMS Library - Week 37, 2025

LabRulez: News from LabRulezGCMS Library - Week 37, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 8th September 2025? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you poster by Agilent Technologies / ASMS and application notes by EST Analytical and Shimadzu!

1. Agilent Technologies / ASMS: Optimizing the Efficiency and Productivity of GC/MS Workflows to Improve Laboratory Sustainability

- Poster

- Full PDF for download

Today, laboratories consume a staggering 10 times more energy and water than a typical office [1]. Labs with GC and GC/MS systems have unique sustainability challenges due to the resource-intensive nature of these instruments. They consume large amounts of gas and energy while also generating hazardous waste products. According to Agilent customer surveys, 85 percent of labs and organizations have sustainability goals in place, and 83 percent of lab leaders believe their current workflow requires optimization to meet their sustainability ambitions [2]. A more efficient laboratory is a more sustainable one. This poster outlines some simple approaches that laboratories can take, today, to optimize workflow efficiency and productivity, thus minimizing resource consumption.

Experimental

Laboratory workflows are the cornerstone of laboratory operations. In this poster we will illustrate the impact of column scaling for GC/MS workflows, the use of hydrogen as an alternative, renewable carrier gas for GC and GC/MS. Hydrogen offers unique safety and reactivity challenges that we will address with Agilent HydroInert source. Lastly, we will demonstrate simple and effective ways to conserve gases, focusing on existing helium carrier gas workflows. In the end, these simple, easy-toimplement practices will illustrate how sustainability can be accomplished in conjunction with improving workflow profitability and productivity.

Alternative Carrier Gases

Carrier Gases

Helium shortages have impacted analytical laboratories since 2006 and repeatedly been in short supply[3]. While helium’s availability has improved in recent years, there are still concerns surrounding supply stability and rising costs. Knowing the cyclic nature of the helium supply chain, exploring alternative carrier gas options like hydrogen and nitrogen are necessary for laboratory managers looking for sustainability, flexibility, and cost savings measures. Specifically, hydrogen carrier gas is a good option for GC/MS methods and when using the Agilent Method Translator tool, methods can easily be transferred. Figure 3 highlights parameter adjustments for translation like pressure, flow, velocity, and temperature program rates to ensure similar relative retention orders with the alternative gas. Hydrogen when compared to nitrogen as a carrier gas provides the best alternative for chromatographic resolution and speed. Figure 4 demonstrates a method transfer of helium to hydrogen carrier gas for ASTM D5769.

Consumables Impact

Tailored GC Columns

Consumables in GC/MS workflows are often overlooked as contributing factors to sustainability and optimization. For example, minimizing column bleed and improving GC column thermal durability can have a major beneficial impacted for both data quality and instrument uptime. Agilent J&W 5Q GC columns provide the lowest bleed standard for GC/MS workflows. This provides less downtime from ion source cleaning, faster conditioning, and minimize reruns due to data quality issues. Figure 5 and 6 highlight thermal stability and sensitivity of the DB-5Q and HP-5Q columns.

Conclusions

Optimizing the efficiency and productivity of GC/MS workflows are critical for analytical laboratories to stay competitive and profitable. This poster demonstrated a time savings of 50% with column scaling from a conventional GC/MS column to a high-efficiency column, successful alternative carrier gas method transfer, reducing potential source reactivity when using hydrogen carrier, and demonstrated 3.8 to 7X factor reduction of carrier gas consumption when using software features and the Helium Conservation module.

2. EST Analytical: Drinking Water Analysis Conditions for USEPA Method 524.3 and the Newly Proposed Method 524.4

- Application note

- Full PDF for download

In June 2009, the United States Environmental Protection Agency (USEPA) promulgated a new drinking water method, 524.3. Due to advances in analytical instrumentation, Method 524.3 allows laboratories to modify purge and trap and GCMS conditions. Currently the USEPA is investigating the option of using Nitrogen as the purge gas in a new drinking water method, 524.4. This application note will explore purge and trap conditions for both Helium and Nitrogen purge gases.

Discussion:

When the USEPA published Method 524.3, they allowed some method flexibility. However, the method still required Helium as the purge gas. Due to fluctuations in the price and availability of high purity Helium, the USEPA has drafted Method 524.4 which would allow for high purity Nitrogen to be used for the purge gas.

Method 524.4 provides the same flexibility as Method 524.3, thus method parameters can be modified in order to optimize purge and trap cycle times. Although the new method allows for a shorter desorb time, moisture build up can still be a problem as the new preservation scheme causes effervescing in the sparge vessel. EST has two features that can aid in moisture control and the “foaming” caused by the effervescing. First, EST has a foam sensor to detect any issues with foaming. The foam sensor for the Encon Evolution has a unique placement above the bulb of the sparge vessel, thus allowing the bulb to control the effervescing bubbles and not sending a false positive signal to the software causing the sample sequence to be aborted. Secondly, the Encon Evolution utilizes an 8 port valve instead of a 6 port valve. This unique engineering has the advantage of excluding the Moisture Reduction Trap (MoRT) from the desorb pathway thus aiding in moisture control for the system. Furthermore, the Centurion WS has the ability of taking samples from the vials without moving the samples. This eliminates opportunities for vial movement errors that would negatively impact productivity.

Experimental:

The EST Analytical Encon Evolution purge and trap concentrator and Centurion WS Autosampler were interfaced to a GC/MSD. The purge and trap concentrator was configured with a Vocarb 3000 (K) analytical trap. A chiller unit capable of keeping the sample vials cooled below 10°C was installed on the Centurion WS autosampler. The experimental parameters are listed in Tables 1 and 2.

Conclusion:

The Encon Evolution and Centurion WS performed very well using both the Helium and Nitrogen purge gases and the 440ml and 390ml purge volumes. The Nitrogen and the Helium purge gases met USEPA method 524.3 criteria. Furthermore, the 440ml purge volume and the 390ml purge volume produced comparable results. Overall, the principal difference between the two purge gases was exhibited in the compound response. When examining the overall compound response factors over the curve range, it is evident that the analytes’ responses are slightly lower with the Nitrogen purge gas as opposed to the Helium purge gas.

3. Shimadzu: Ultra-Sensitive Analysis of β-cyclocitral in Water Using Solid Phase Micro Extraction and Gas Chromatography–Mass Spectrometry

- Application note

- Full PDF for download

User Benefits

- SPME-GC-MS supports effective monitoring of water environments

- Excellent sensitivity, achieving quantification of β-cyclocitral in water within the ultra-trace level

- SPME provides a solvent-free extraction, efficient, and highly sensitive method for detecting β-cyclocitral

Cyanobacterial blooms, commonly known as algal blooms, cause rivers and lakes to turn vividly green due to the excessive growth of cyanobacteria. This phenomenon is caused by factors such as global population growth, industrial pollution, and rising water temperatures caused by climate change. 1)

Cyanobacterial blooms produce volatile organic compounds (VOCs) like β-cyclocitral and β-ionone, which cause unpleasant odors and reduce the quality of drinking water and aquatic products. This leads to consumer complaints and economic lossesin aquaculture and water treatment.

Detecting and quantifying β-cyclocitral (Figure. 1) at trace levels is therefor essential for effective water management. However, conventional solvent extraction methods often fail to detect βcyclocitral, as it requires acidification or heating to be effectively released from the matrix. 2)

In contrast, solid phase microextraction (SPME) enables efficient detection by facilitating the thermal desorption of β-cyclocitral from sample matrices onto the fiber. Moreover, SPME reduces solvent use and shortens sample preparation time compared to traditional extraction techniques, making it a suitable approach for the analysis of thermally induced volatile compounds like βcyclocitral.

This application news describes the suitability of β-cyclocitral analysis using SPME automatic injection (AOCTM-6000 Plus) and GCMS-QP2020 NX of Shimadzu. The developed method enables highly sensitive quantitation of β-cyclocitral, achieving detection at the pg/mL level.

Analytical Conditions

β-cyclocitral in water was analyzed using GCMS-QP2020 NX of Shimadzu equipped with the AOC-6000 Plus autosampler as shown in Figure 2. The detailed analytical conditions of instrument was provided in Table 1. For the SPME analysis, 50/30 μm DVB/CAR/PDMS fiber was used, and SH-PolarWax (30 m × 0.25 mm I.D., 0.25 μm) was used as the analytical column. The AOC-6000 Plus supports various injection techniques, including liquid injection, headspace (HS) injection, and solidphase microextraction (SPME) injection. Furthermore, sample preparation and preprocessing in the AOC-6000 Plus are automatically carried out during injection into the GC system, improving efficiency and reproducibility.

Conclusions

In this application news, SPME-GC-MS method was developed and validated for the ultra-sensitive quantitation of β-cyclocitral in water using the Shimadzu GCMS-QP2020 NX coupled with the AOC-6000 Plus. The method demonstrated quantification capability down to the picogram-per-milliliter (pg/mL) level, excellent linearity (R² > 0.999). Accuracy and precision were confirmed with a recovery of 105.3% and %RSD of 0.7. These results confirm the reliability and suitability of the SPME-GC-MS method for ultra-trace quantification of β-cyclocitral in environmental watersamples.