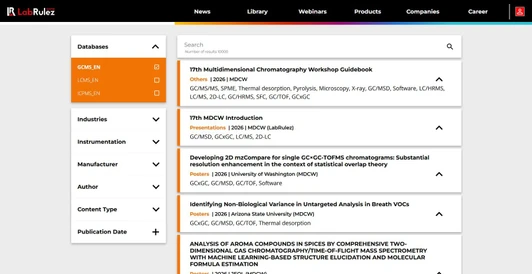

News from LabRulezGCMS Library - Week 29, 2025

LabRulez: News from LabRulezGCMS Library - Week 29, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 14th July 2025? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you posters by Agilent Technologies / ASMS, Shimadzu / ASMS, presentation by Liège University / MDCW and technical note by Thermo Fisher Scientific!

1. Agilent Technologies / ASMS: Optimizing Hydrogen Carrier Gas on GC/MS Using the HydroInert EI Source and 5Q Columns

- Poster

- Full PDF for download

Hydrogen is widely recognized for its benefits in gas chromatography (GC), including cost-effective generation in the lab, rapid chromatography, and higher sample throughput. However, its reactivity can lead to hydrogenation and dechlorination reactions in the mass spectrometer electron ionization (EI) source, complicating its application in many scenarios. To address these issues, Agilent has developed a specially designed extractor source for the Inert Plus GC/MSD and triple quadrupole GC/MS systems, enhancing performance with hydrogen carrier gas. The Agilent HydroInert source maintains mass spectral fidelity and allows users to utilize existing helium-based mass spectral libraries.

This study investigates how the 5Q series of columns impact the performance and durability of the HydroInert source tune. The study involved cycling through 10,000 oven temperature ramps without any injections to assess the effects of column bleed from the 5Q phase. Furthermore, the study examined how the combination of sample matrix and column bleed from the 5Q phase affects source longevity.

Experimental

HydroInert Functionality with 5Q Columns (no Injection)

An experiment was designed to investigate the effects of ultra low bleed columns (HP-5Q) on the functionality of the HydroInert source over time. A method simulating a large oven temperature ramp cycle (Table 1) over 12 minutes was created. The syringe was removed from the ALS tower to simulate injections, but to isolate the source of siloxanes to column bleed from the HP-5Q only. 10,000 injections were executed, and a system tune was performed every 100 injection to monitor source parameter shifts.

The Agilent 7000E was run in SCAN mode, scanning from 50-450 m/z during each run. Air leaks were detected and immediately remedied when found to ensure the experiment was free from oxides. Liner and septum were not changed during this experiment.

Results and Discussion

HydroInert Functionality with 5Q Columns (no Injection)

Results of the effects of 10,000 oven temperature cycles on the HydroInert source tune parameters are shown in Figure 2. Repeller and ion body voltages are set automatically by the tune algorithm to maximize the transference of ion on the 7000E. Throughout the 10,000 injections the ion body voltage remained stable. The EM voltage gain across 10,000 injections was as expected. The source was in use for 120,000 minutes during this study and data was being collected throughout the duration of the study in SCAN mode. During this study, three leaks were detected at the MS transfer line and were corrected as soon as they were detected. The leaks are reflected in the spike in O2 percentage. A new ion body will typically have a voltage of 16-22 V on a HydroInert source. When an ion body begins to lose functionality the ion body voltage will begin to rise to compensate for the loss. Eventually the ion body voltage tops out at 29-30 V and the tune begins to show lower abundance of tune ions, until the source fails to tune. In the current study the ion body voltage was set by the tune algorithm between 19-24 V. This is a stable and normal operating range for the ion body. It is important to remember that a single elevated ion body tune is not cause for concern, there needs to be a trend of elevation over time. The overall purpose of this first study was to examine what baseline changes would occur to the HydroInert tune parameters when using a 5Q column in leak free conditions. Water and oxygen are known to speed the liberation of column bleed, which in turn reduces the functionality of the HydroInert source. This study shows that under leak free conditions, with a 5Q column, the HydroInert source can function optimally for an extended period. This study adds to a growing body of evidence that has demonstrated one of the main factors in HydroInert longevity is leak state of the system.

Conclusions

Agilent HydroInert source longevity is dependent on application and method conditions. However, by using the best practices highlighted above, the longevity of HydroInert parts can be prolonged. The HydroInert source cannot be mechanically or chemically cleaned, thus when source parts show reduced functionality, replacement of the recommended parts is required to restore functionality. Replacement intervals will be method and application dependent.

2. Liège University / MDCW: MOSH&MOAH in food ingredients and additives and the advantages of using LC/GC×GC(-FID/TOFMS) for their analysis

- Presentation

- Full PDF for download

This presentation by Aleksandra Gorska and colleagues (Gembloux Agro-Bio Tech) addresses the analysis of MOSH (mineral oil saturated hydrocarbons) and MOAH (mineral oil aromatic hydrocarbons) in food ingredients and additives, particularly those derived from oils and fats. These contaminants are widespread in the food chain due to packaging, lubricants, or storage conditions. While MOSH can accumulate in human tissues, MOAH—especially those with three or more aromatic rings—pose genotoxic risks. The European Food Safety Authority (EFSA) has recently emphasized a lack of data on such impurities in food additives.

To fill this gap, the researchers developed and applied an advanced analytical workflow based on HPLC-GC×GC-FID/TOFMS, replacing the traditional HPLC-GC-FID approach. This multidimensional technique combines high-resolution separation with both flame ionization detection (FID) and time-of-flight mass spectrometry (TOFMS), allowing detailed structural characterization, efficient removal of interfering compounds, and the ability to separate MOAH by the number of aromatic rings.

Key benefits of the HPLC-GC×GC-FID/TOFMS system include clearer chromatograms with structured elution patterns, improved purification and separation of complex MOAH profiles, and identification of contamination markers such as DIPN (indicating migration from recycled packaging). Additionally, the system enables simultaneous quantification of MOAH and polycyclic aromatic hydrocarbons (PAHs), which have distinct analytical requirements and toxicological profiles.

The study concludes that, despite its complexity, the HPLC-GC×GC-FID/TOFMS technique provides substantial analytical advantages and aligns with EFSA’s recommendations. It offers a powerful tool for ensuring food safety in products containing oil- or fat-derived additives, enabling more accurate risk assessments and source tracking of contamination.

3. Shimadzu / ASMS: Highly sensitive and efficient analysis of aroma components using trapped Headspace GC-MS

- Poster

- Full PDF for download

The aroma composition of foods has been the subject of considerable research in recent years. It is well known that the presence of volatile compounds and their composition determine the specific aroma of foods and the flavor of the resulting products. Static headspace technique enables high sensitivity analysis of volatile compounds, normally extracting 1 mL of headspace. But in situations where it is necessary to evaluate the total chemical profile, it is known that components in small quantities also affect the overall aroma. Thus, the HS-20 NX was used running in "Trap mode", where by using trapped headspace sampling, it is possible to extract much more volume and analyze, not only the majority components, but all the compounds with high sensitivity.

The system used to achieve the highest sensitivity is the HS-20 NX coupled to the GCMS-QP2020 NX single quadrupole mass spectrometer.

Results and Discussion

After the incubation time, the acquisitions were done by loop mode and trap mode with 3- and 5-times sample concentration. In this way, it is possible to analyze, via trap, the presence of compounds at trace levels, which cannot be observed when analyzed in loop mode. 18 compounds could be identified in the sample when analyzed in loop mode, whereas in trap mode, 35 were identified.

Some components such as benzene acetaldehyde, gammacaprolactone, methyl butyrate, o-guaiacol, that have a decisive influence on the overall aroma and flavor were detected only in the trap mode, due to their low concentrations in the sample. Even concentrating the sample 5-times in the trap, it was possible to detect these compounds that require greater sensitivity along with compounds present in high concentrations in the sample, such as butanoic acid, acetic acid, and others, without losing analysis efficiency.

Conclusion

The improvement in analysis sensitivity when using trap mode can be observed when comparing the area for some components with a major impact on the overall aroma but present in small quantities. When concentrating the sample 3-times in the trap, the peak intensities increased from 351.17 to 1401.08%. And it was still possible to have a significant increase of another 168%, on average, by concentrating the sample 5-times. The peak intensities increased from 521.48 to 2517.86% compared to loop mode analysis.

These analyses demonstrate that trapped headspace can be used to determine an overall aroma profile in a single analysis and with a single trapping material. The trapped headspace sampler enables ultra sensitivity analysis, identifying compounds at low concentrations which were undetectable with conventional headspace samplers.

4. Thermo Fisher Scientific: Data-driven GC and GC-MS instrument monitoring with SmartStatus intelligent software

- Technical note

- Full PDF for download

Rising costs can significantly impact an analytical laboratory’s profit margin, and it is crucial to maintain productivity and ensure maximum asset utilization to stay competitive. To balance increased overhead costs, including analytical gases and staff pay, laboratories must ensure that analytical instrumentation consistently produces results, without interruption. Re-analyzing entire runs due to drops in sensitivity, unnecessary downtime, and underutilization of consumables is expensive and time consuming.

Thermo Scientific™ SmartStatus™ instrument tracking can help laboratories realize additional cost savings. This is done by using data-driven insights to accurately determine when to perform maintenance and replace consumables and parts, so that the system consistently runs smoothly for all samples and meets specifications in the initial analysis. This ensures that consumables and parts are replaced on the correct schedule and avoids excess instrument downtime.

SmartStatus instrument tracking is an intelligent instrument health software that allows users to track key aspects of their GC-MS system. It is available as standard on the Thermo Scientific™ TRACE™ 1600 GC series, Thermo Scientific™ AI/AS 1610 liquid autosampler, Thermo Scientific™ ISQ™ 7610 GC-MS series, and the Thermo Scientific™ TSQ™ 9610 GC-MS/MS series. In this technical note, the new SmartStatus instrument tracking capabilities are highlighted with examples of how it can enable analytical laboratories to keep instruments producing consistent results.

SmartStatus software overview

SmartStatus intelligent software, available within Thermo Scientific™ Chromeleon™ Chromatography Data System (CDS), allows monitoring of the entire analytical system including Thermo Scientific™ autosamplers, GC, GC detectors (FID and TCD), and mass spectrometers (MS). Hundreds of key instrument parameters are monitored by SmartStatus software, which provides real-time data and insights informing the user to potential problems before they arise to ensure maximum instrument uptime. This allows users to make informed decisions on which parts of the analytical system require attention and when. By performing preventative maintenance using data-driven guidance, optimal instrument performance is sustained day in and day out. Figure 1 shows the SmartStatus software overview page for a TSQ 9610 triple quadrupole MS coupled to a TRACE 1610 GC and AI/AS 1610 liquid autosampler. This overview page allows a user to quickly determine if the system is ready to run or requires attention.

For more information on instrument status, there is a detailed view for each part of the system. This next level view shows how many injections have been performed for the various GC consumables, the lifetime of the MS detector and filament, and when the last tune was performed. Figure 2 shows an example of the GC and MS parameters and how they are monitored. Each parameter is represented as a counter gauge. As the usage increases, the gauge changes color to quickly notify the user of any maintenance that is required or will be needed soon. This allows users to plan maintenance in advance to fit it around their schedule and workload. SmartStatus instrument tracking can be monitored directly in Chromeleon CDS, and consumables usage can also be monitored directly on the TRACE 1610 GC touch screen through the dedicated instrument health icon, as shown in Figure 3.

The ISQ 7610 GC-MS and the TSQ 9610 GC-MS/MS detector lifetime is monitored using a predictive algorithm. This assesses the voltages on the detector and predicts the lifetime remaining on the system so that preventative maintenance can be planned. As the ISQ 7610 GC-MS and TSQ 9610 GC-MS/MS are equipped with the XLXR™ electron multiplier detector as standard, the lifetime of the detector is several years.1 By monitoring the detector intelligently, users can avoid unnecessary downtime. Figure 4 shows monitoring of the detector within SmartStatus software.