News from LabRulezGCMS Library - Week 42, 2024

- Photo: LabRulezGCMS Library

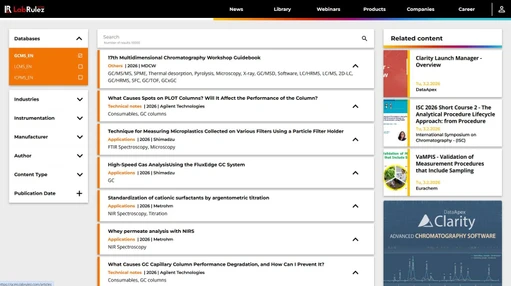

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 14th October 2024? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring to you applications by Agilent Technologies, Thermo Fisher Scientific, and posters by Shimadzu and LECO!

1. Shimadzu: Interlaboratory comparison study of two gas chromatography injection techniques viz. liquid and dynamic headspace for trace level quantification of Ethylene Oxide (EtO) and 2-Chloroethanol (2-CE) in ginger powder sample by using tandem mass spectrometry

- Poster / AOAC

Purpose

EtO is one of the most widely produced chemicals worldwide. It is colorless, odorless, flammable gaseous cyclic ether with boiling point of 10.4°C. It has a very strong antibacterial property. Due to its small size, it shows a high diffusivity and strong penetrating properties and is thus very effective in the disinfestation / disinfection of food commodities. EtO is highly carcinogenic, mutagenic and genotoxic impurity for living being. The US National Institute of Health (NIH) classified EtO as “known to be a human carcinogen based on sufficient evidence of carcinogenicity from studies in humans, including epidemiological studies and studies on mechanisms of carcinogenesis.” Considering carcinogenicity and no acceptable threshold for exposure, no Acceptable Daily Intake (ADI) was established for EtO.

2-CE, which is one of the prominent metabolite of EtO is also considered to be genotoxic and potentially carcinogenic. Given the inconclusive toxicological picture of 2-CE, it was decided by regulatory authorities to follow the precaution approach and consider 2-CE equally toxic to EtO. Hence it is very important to quantitate EtO and 2-CE in food matrices at trace levels. EU-MRLs (Maximum Residue Levels as per European Commission) for EtO and 2-CE are summarized in Table 1.

Various methods have been presented in EURL-SRM-Analytical Observation Report for the analysis of EtO and 2-CE. The choice of the analytical approach depends on both the analytes and the matrix to be analyzed. So, it is important to have a detailed comparison study of different analytical approaches to ensure robustness, reliability and accuracy of the method for the quantification of EtO and 2-CE.

This study covers the comparison between liquid injection technique and dynamic headspace injection technique using different extraction processes for ensuring highest extraction efficiencies. Incurred sample is used for this study.

Conclusion

- In comparison between liquid and HS-Dynamic mode, it is evident that HS Dynamic has advantage in method optimization for accurate recoveries. Liquid extraction needs multiple trials to ensure complete extraction of analytes, majorly depending on matrix. Similarly, temperature and extraction time also plays a critical role

- Quantification of EtO and 2-CE impurities in ginger powder sample was successfully performed by using Shimadzu GCMS-TQ8050 NX with AOC-20i/s and HS-20 NX dynamic headspace samplers

- HS Dynamic requires less sample preparation, demonstrates high recovery due to closed system, high accuracy and easy method optimization

2. Agilent Technologies: Estimation of Hydrogen Phosphide (Phosphine) Residues in Cereals and Spices Using the Agilent 8697 Headspace Sampler and GC/MS/MS

- Application

Abstract

This application note demonstrates the use of an Agilent 8890 GC system coupled with the Agilent 8697 headspace sampler and Agilent 7010 GC/TQ to detect and quantify hydrogen phosphide (phosphine) residues in rice and red chili powder. The sample was inserted into a headspace vial and Milli-Q water was added. The vial was crimped and loaded into the headspace sampler, followed by GC/MS/MS analysis. The limit of quantification of 5 ng/g was achieved in rice and red chili powder matrices. Average recoveries ranged from 80 to 110% in various recovery experiments.

Introduction

Fumigants are gases used for controlling pests in stored food products.1 Cereals are mainly disinfected by hydrogen phosphide (commonly known as phosphine) and liberated from stable salts such as zinc phosphide or aluminum phosphide.1 Phosphine is a colorless gas that is used as a fumigant worldwide because of its rapid diffusion and extreme volatility.1 Despite these desirable properties, trace amounts of phosphine may persist in foods several months after treatment and can cause severe health problems.1

Due to its high volatility, phosphine is not amenable to club with common multiresidue methods for pesticide residue analysis in food. Thus, special single-residue methods must be applied.2 Previously, methods for the analysis of phosphine have been developed that highlight the use of the Tenax-filled inlet liner along with cryogenic cooling to preconcentrate the phosphine prior to chromatographic separation. These methods require heavy analytical configurations that include a liquid nitrogen handling system. In EU legislation, maximum residue limits for phosphine in foodstuffs range from 0.01 to 0.1 mg/kg, depending on the commodity (Commission Regulation (EC) No. 149/2008).2

The method adopted in this application note demonstrates the use of the 8697 headspace sampler for sample introduction to the 8890 GC system coupled with the 7010 GC/TQ.

Column configuration

To prevent single, loose particles of the PLOT column stationary phase from entering the ion source of the mass-sensitive detector (MSD), a restriction capillary (1 m × 0.15 mm) was inserted between the PLOT column and the MSD using a purged Ultimate union. This configuration also helps in column replacement without venting the mass spectrometer.

Conclusion

An accurate and rugged method was developed which meets the requirements of the European Union reference laboratory (EURL) for maximum residue limits of phosphine in foodstuffs. This ranges from 0.01 to 0.1 mg/kg, depending on the commodity (Commission Regulation (EC) No 149/2008) for the analysis of phosphine in rice and red chili powder. The LOQ of the method was demonstrated at 5 ng/g for all tested matrices. Repeatable results were found for four successive replicates of matrix-based standards at 20 ng/g concentration levels. Excellent recoveries were obtained in all tested matrices at 10 ng/g spiked concentration levels. Thus, this study demonstrates the usefulness of the developed method for routine analysis of food samples for phosphine analysis at trace levels.

3. Thermo Fisher Scientific: Trace analysis of polychlorinated dibenzo-p-dioxins/ dibenzofurans using GC-MS/MS in accordance with EU Regulations 2017/644 and 2017/771 for food and feed

- Application

Goal

To demonstrate the suitability of the Thermo Scientific™ TSQ™ 9610 triple quadrupole GC-MS/MS system with Thermo Scientific™ Chromeleon™ Chromatography Data System (CDS) software for the routine and regulatory compliance testing of polychlorinated dibenzo-p-dioxins and polychlorinated dibenzo-p-furans (PCDD/Fs) in food and feed samples in accordance with Commission Regulations (EU) 2017/644 and 2017/771.

Introduction

Polychlorinated dibenzo-p-dioxins/dibenzofurans (PCDD/F), or dioxins as they are commonly referred to, are classified as persistent organic pollutants (POPs) under the Stockholm Convention. Due to their chemical stability and high fat solubility, these chemicals can accumulate within food chains and pose exposure/health risks to humans through consumption of food items (i.e., diary, meat, and fish). Regulations are in place to monitor food and feed for the presence of dioxins to protect the population.1 Current maximum levels allowable for PCDD/Fs in food and feedstuffs are at the pg·g-1 concentration range due to the toxicity risk they pose.2,3 However, the European Commission has announced plans to lower the current maximum levels in certain feedstuffs in 2024 based an updated risk assessment.4 As of 2014, a change of EU regulations permitted the use of gas chromatography-triple quadrupole mass spectrometry (GC-MS/MS) for the analysis of food and feed as an alternative to GC–high-resolution mass spectrometry (GC-HRMS).5,6 With the proposed lowering of some maximum levels, performance of current instrumentation to achieve these targeted limits must be assessed.

Achieving these targeted limits places further stress on laboratories in maintaining consistent sensitivity to detect the trace levels of dioxins in difficult food matrices. Another challenge for analysts is the time-consuming data assessment based on regulatory requirements for PCDD/F analysis. Often the

necessary tools for PCDD/F quantification (i.e., isotopic dilution quantification) and reporting of regulatory requirements (ion ratio, calibration, and response factor deviation)7,8 do not exist within a single software. This requires analysts to export to external packages (i.e., Microsoft™ Excel™ ) to perform critical calculations leading to transcription errors and added time for reporting. In addition, laboratories must ensure they produce consistent data throughout the analytical run to avoid reanalysis or re-extraction when sample/extract material is limited.

In this analysis, the performance of the TSQ 9610 triple quadrupole GC-MS/MS system equipped with the Thermo Scientific™ NeverVent™ advanced electron ionization (AEI) source was used to demonstrate compliance for regulatory limits for PCDD/F in food and feed samples in accordance with EU Regulations. Food and feed samples were provided by the European Union Reference Laboratory for halogenated Persistent Organic Pollutants in feed and food (EURL POPs) (Germany) and Wageningen Food Safety Research, in their capacity as National Reference Laboratory for POPs (NRL POPs, The Netherlands). These samples contained known trace levels of dioxins previously confirmed at the respective institutes or in international proficiency tests. The aim of this analysis was to ensure results were consistent with the previously determined concentrations in food and feed matrices and meet current compliance with the EU regulations.

Conclusion

The results of these comprehensive experiments demonstrate that the TSQ 9610GC-MS/MS system, configured with the NeverVent AEI source and controlled using Chromeleon CDS software together with the Dioxin Analyzer eWorkflow, can deliver reliable regulatory-compliant performance for the quantification and confirmation of PCDD/Fs food and feedstuffs:

- Femtogram level sensitivity performance for ultra trace level determination of PCDD/F within food and feed samples.

- Check standard performance was within quantitation and ion ratio thresholds for regulatory method compliance at femtogram levels.

- Accurate and precise quantitation at maximum levels and action thresholds for PCDD/F in food and feed.

- Chromeleon CDS software, version 7.3, provides an integrated platform, with the ability to automatically setup, easily acquire, process and report compliant data in a fully regulated environment, eliminating the need for using external spreadsheet programs.

- Chromeleon eWorkflows, available from Thermo Fisher Scientific also provide error-free execution of each analysis to meet standard operating procedure (SOP) requirements, further simplifying the user experience.

4. LECO: Characterization and Comparison of Basil Before and After Drying Using GC, GCxGC, and TOFMS

- Poster

INTRODUCTION

GC and MS are well-established techniques for the characterization of food, beverage, and flavor samples. Extending the analytical separation to two

dimensions with comprehensive two-dimensional gas chromatography (GCxGC) enhances the peak capacity, allows for exploring more complex samples, and allows for determining more individual analytes within complex samples. TOFMS adds to these benefits and often leads to the identification for these isolated analytes, supporting non-target analyses where analytes of interest and importance can be determined through data evaluation. When coupled together, the benefits are often greater than the sum of the individual techniques.

Software tools that compare sets of GCxGC samples facilitate these analyses and can effectively reveal useful information from the rich data. In this work, we evaluate the aroma characteristics for basil before and after drying. This type of characterization can be useful for quality control, product development, and batch comparisons, as well as understanding the sensory profile changes associated with curing.

CONCLUSIONS

In this work, LECO’s TGM800 was used to determine the moisture level of fresh and cured basil samples and LECO’s Pegasus BT4D GCxGC-TOFMS with ChromaTOF Tile were used to highlight differences between the chemicals which contribute to the sensory profiles of fresh and cured basil. This provided a better understanding of the aroma characteristics of these samples. Many differences were observed between the samples and the analytical tools used

in this work were crucial for their determination.