News from LabRulezGCMS Library - Week 04, 2026

LabRulez: News from LabRulezGCMS Library - Week 04, 2026

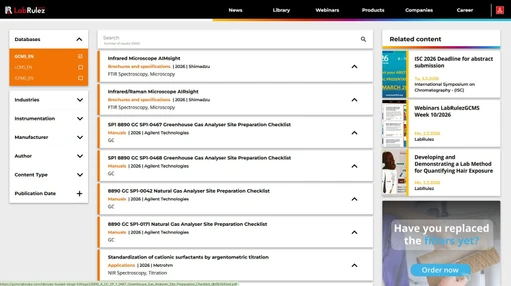

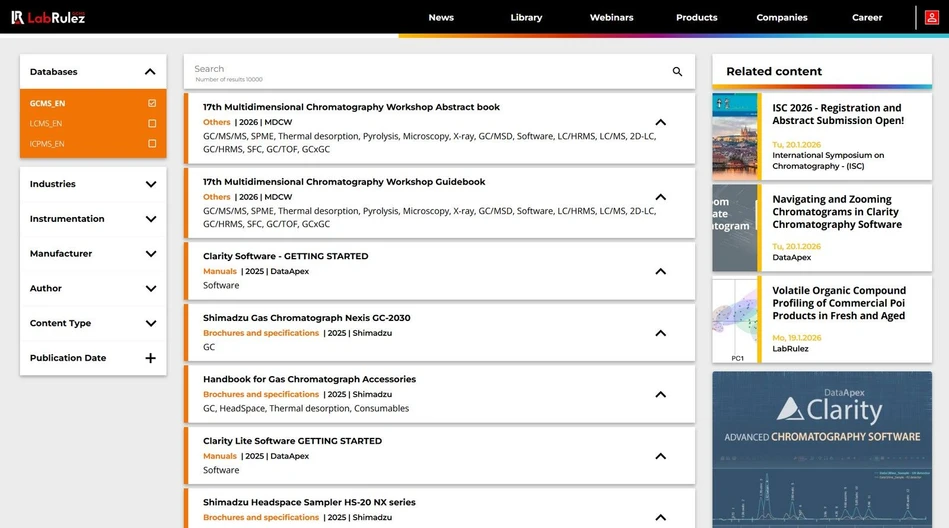

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 19th January 2026? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you application notes by Agilent Technologies, BaySpec and Metrohm!

1. Agilent Technologies: Micro GC Analysis of Permanent Gas Impurities in PEM Fuel Cell-Grade Hydrogen

According to SAE J2719, ISO 14687, EN 17124, and ISO 19880-8

- Application note

- Full PDF for download

Quality requirements for hydrogen purity vary with application. Proton Exchange Membrane (PEM) fuel cell hydrogen is the application with the most stringent specification. Hydrogen purity specifications for other applications, i.e. residential or industrial use, typically allow for higher levels of specific contaminants.

For PEM fuel cell-grade hydrogen, there are several key methods regulating quality. Some methods may also cover other scopes, but where they pertain to PEM fuel cell-grade hydrogen, they align on specific requirements for purity level and limit concentrations of specific contaminants.

- SAE J2719 specifies hydrogen fuel quality requirements for PEM fuel cell vehicles, such as hydrogen-powered cars.

- ISO 14687 specifies minimum quality characteristics of hydrogen fuel for various applications, including residential, commercial, industrial, stationary systems, and vehicular use.

- EN 17124 specifies the quality characteristics of hydrogen fuel dispensed at hydrogen refueling stations for use in PEM fuel cell vehicle systems.

- ISO 19880-8 specifies the quality of the gaseous hydrogen at hydrogen distribution facilities and hydrogen fueling stations for PEM fuel cells for road vehicles.

Micro GC is a suitable choice of technique for covering analysis of permanent gases in ultra high purity (UHP) hydrogen (oxygen, nitrogen, argon, helium, and methane). The small internal volume of the MEMS-based µTCD in the Agilent 990 Micro GC means that lower detection levels can be achieved when compared to regular TCDs, allowing for detection of contaminants in the single-digit ppm range. Note that ammonia, carbon monoxide, carbon dioxide, and formaldehyde can also be detected with Micro GC; however, additional/different columns might be required. Sensitivity requirements below 1 ppm may require alternate techniques.

Experimental

The method developed covers permanent gases defined in SAE J2719, and by default, also ISO 14687, ISO 19880‑8, and EN 17124. The 990 Micro GC system was set up similar to the method described in Agilent application note 5994‑2138EN.1 A 20 m MS5A straight channel on hydrogen carrier gas was used. Table 2 lists experimental conditions for method development. A 20 m molsieve provides sufficient separation for the argon/oxygen peak pair at low-ppm concentrations.2 For best results, the column was operated at a low temperature of 30 °C. Hydrogen was used as carrier gas to completely mask the bulk hydrogen matrix peak, resulting in separation of the helium and neon baseline3 , while still allowing for a similar sensitivity as with the helium carrier. The hydrogen carrier allows helium (He), argon (Ar), oxygen (O2), nitrogen (N2 ), methane (CH4 ), and even neon (Ne) to be measured at their required levels. Carbon monoxide (CO) that elutes from the molsieve column is not part of the scope. SAE J2719 requires these to be measured at the sub-ppm level, which is too low for Micro GC. Table 3 lists the composition of calibration gas used. The system was calibrated using single‑point calibration.

Conclusion

The Agilent 990 Micro GC setup, described with a single 20 m straight molsieve column running hydrogen carrier gas is capable of meeting the hydrogen quality requirement in SAE J2719 and other comparable UHP hydrogen methods for select permanent gases (He, Ar, O2, N2, CH4 ). The critical component, oxygen, can reliably be measured below the required five ppm level. Precision and accuracy are excellent for all components, and with a short runtime of five minutes, this analytical option can deliver 10–12 runs per hour. Detection of other components listed in SAE J2719, i.e. ammonia or CO/CO2 , will require different equipment.

2. BaySpec: Detecting Toxins on Cannabis Leaves with Portable Miniature Mass Spectrometer

- Application note

- Full PDF for download

Mass spectrometry in connection with different separa‐ tion techniques currently represents the main analytical approach for determination of residual pesticides in the Food & Agriculture industry. Traditionally, samples need to be collected and sent to a laboratory for analysis using techniques such as GC‐MS or HPLC‐MS, which are costly and time‐consuming. In addition, the conventional mass spectrometer usually requires laborious sample pre‐ treatment, which does not allow for immediate in‐situ sample determination.

Presented in this application note are data from a ther‐ mal desorption electrospray ionization (TD‐ESI) or atmso‐ pheric pressure chemical ionization (APCI) source coupled to a portable mass spectrometer for toxin screening of cannabis leaves.

Bayspec’s Portability mass spectrometer is less than 10 kg, highly portable, and battery‐operated. Its linear ion trap mass analyzer can perform fast in‐field detection of analytes, including residual toxins, by direct sampling of the surfaces of fresh food and plant products without any sample pre‐treatment. In this study, BaySpec’s sampling probe was used to directly swab the surface of cannabis leaves and inserted into the TD‐ESI or APCI sample inlet system for real time analysis. Four different samples were studied:

- Fresh cannabis leaves

- Fresh cannabis leaves sprayed with PBO

- Fresh cannabis leaves sprayed with myclobutanil

- Fresh cannabis leaves sprayed with paraquat

All sprayed samples were air‐dried prior to screening. No sample preparation was done to test the leaves. Both TD‐ ESI and APCI ionization methods tested positive for THC and toxins where applicable. See Figure 3 for recorded spectra.

Due to short analysis times (1‐5 seconds per sample), this technique allows for fast screening for applications in food and environmental safety. MS (as well as MS/MS) analyses can be performed on surface‐residual toxins at parts per billion levels. The TD‐ESI ion source with PortabilityTM miniature mass spectrometer is available from BaySpec.

This system does not require any add‐ itional support, external po‐ wer or gases. The simple in‐ tuitive software interface is operated by touch screen and makes the instrument ex‐ tremely easy to control. The external TD‐ESI source is fully integrated into the main software environment and the turn‐key system is user‐ friendly, does not require excessive training, and can be operated by persons with no previous mass spectrometry experiences

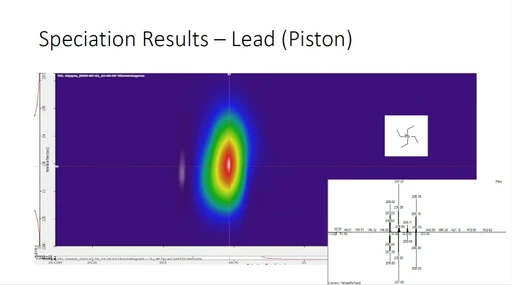

3. Metrohm: Monitoring phosphate reactions in real time with Raman spectroscopy

- Application note

- Full PDF for download

CURRENT METHODES FOR REACTION ANALYSIS

Titration is highly effective for quantifying phosphate and sulfate species to determine reaction completion and final product composition in fertilizers. Gravimetric analysis is used to quantify insoluble byproducts like gypsum (CaSO4·2H2O). Both techniques require sample collection, hazardous reagents, and manual processing – all of which introduce time delays and incur costs with every measurement. This Application Note describes how Raman spectroscopy was used as an alternative method to monitor a simplified phosphate fertilizer production process under laboratory conditions.

METHOD

Raman spectroscopy is well suited to monitor phosphate species due to its high selectivity and nondestructive nature. Furthermore, it can simultaneously detect sulfate ions, enabling real-time analysis of multi-component reaction systems. In this study, dicalcium phosphate (CaHPO4, hereafter referred to as DCP) is used as a model compound for phosphate rock. In a 100 mL beaker, 500 mg of DCP was dissolved in 10 mL of 0.5 mol/L hydrochloric acid (HCl) (Equation 1). To simulate industrial reaction conditions and introduce sulfate ions, 0.25 mL of 1.0 mol/L sulfuric acid (H2SO4) was then added. The use of low-concentration HCl ensures safe handling and facilitates clear identification of the sulfate (SO42−) Raman peak.

CONCLUSION

Raman spectroscopy proved to be an effective tool for monitoring a phosphate fertilizer production process, providing clear insights into phosphate speciation, sulfate concentration, and precipitation dynamics. Raman spectral changes revealed transitions in phosphate protonation states and the formation of calcium-based precipitates. These capabilities support enhanced process control and product quality in phosphate fertilizer manufacturing.