A Better Path for Industrial GC Users — How the TRACE 1600 Series GC Delivers Reliability, Innovation, and Seamless OpenLab CDS Integration

- Photo: Thermo Fisher Scientific: A Better Path for Industrial GC Users — How the TRACE 1600 Series GC Delivers Reliability, Innovation, and Seamless OpenLab CDS Integration

- Video: Carlos & Dario Tettamanzi: Thermo Fisher Scientific - "Trace 1600 Series GC"

Industrial laboratories have some of the most demanding analytical environments in the world. Whether monitoring refinery processes, ensuring product purity in petrochemical plants, or supporting quality control in chemical manufacturing, these labs rely on gas chromatography (GC) every hour of every day. Uptime, reproducibility, and serviceability are not “nice to haves” — they are mission-critical.

Thermo Fisher Scientific: A Better Path for Industrial GC Users — How the TRACE 1600 Series GC Delivers Reliability, Innovation, and Seamless OpenLab CDS Integration

Thermo Fisher Scientific: A Better Path for Industrial GC Users — How the TRACE 1600 Series GC Delivers Reliability, Innovation, and Seamless OpenLab CDS Integration

Frequent hardware failures, diminishing vendor responsiveness, and limited innovation may create pressure points for many labs already operating under lean staffing and nonstop production demands. However, the most common reason industrial labs hesitate to evaluate alternative GC systems is not hardware-related — it’s software-related. One perceived obstacle often holds them back: We can’t change our CDS!

This hesitation makes perfect sense. Industrial labs often run anywhere from a dozen to fifty or more GCs in a familiar and well-integrated software environment. Every method is validated in it. Every QA and data integrity process depends on it. These labs run lean, often 24/7, and they simply don’t have the time, or the appetite, for a software migration. Even the idea of retraining operators is enough to stop the discussion before it starts.

The industrial GC market is ready for change

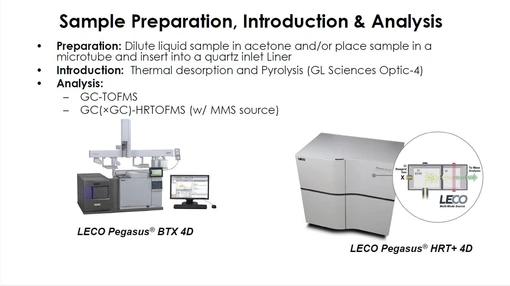

The Thermo Scientific TRACE 1600 Series GC and the Thermo Scientific AI/AS 1610 autosampler, including the high-throughput dual-channel Gemini configuration, have been recently fully integrated into one of the most popular chromatography data systems in the industrial laboratories, Agilent OpenLab CDS.

With the new SII 1.3 driver the TRACE 1600 and 1610 GC show up inside OpenLab just like the instruments customers are used to, giving users a modern, robust GC platform without disrupting the software environment they depend on. The integration is fully supported across the most commonly installed OpenLab versions 2.6, 2.7, 2.8, and 2.84, and works seamlessly in Windows 11 systems.

In other words, labs don’t need to change their CDS at all. They don’t need to modify workflows, rewrite methods, or retrain their teams. They can keep everything exactly as it is, from the user interface to the reporting structures, while simply upgrading to a new, reliable hardware. For many laboratories, this alone removes the biggest barrier to exploring something new.

Designed for the realities of industrial GC analysis

The TRACE 1600 Series GC were built with industrial environments in mind, and that shows up in ways users immediately appreciate. For starters, the system emphasizes reliability and uptime. Its Integrated Electronic Control (IEC) is engineered for long-term stability, and the overall hardware is designed to stay online through continuous, high-throughput use.

Another key benefit of the TRACE 1600 Series GC is modularity. Anyone who has worked in an industrial lab knows that maintenance windows are tight, and every minute counts. The TRACE 1600’s modular design makes it easy to access injector and detector modules, swap parts quickly, and get the instrument back online with minimal disruption. It also means that service visits tend to be smoother and faster, something that matters enormously in an environment where production schedules don’t stop.

Flexibility is another important aspect. Industrial workflows aren’t all the same, and the TRACE 1600 Series supports a wide range of self-installable inlet and detector modules, from SSL, SSL-HeSaver and PTV to FID, TCD, ECD, NPD, FPD, and PDD, offering unlimited configurations available when needed, for applications ranging from basic QC to more complex analyses. Additionally, the modules are fully exchangeable between Thermo TRACE GC systems, getting the most out of the existing GC system in the lab.

Many labs also appreciate that the TRACE 1600 Series uses common consumables, meaning they don’t have to overhaul their purchasing processes or introduce new suppliers.

When you put all this together, the reliability, the modularity, the application flexibility, and the drop-in OpenLab CDS compatibility, the result is a GC platform that genuinely makes life easier for industrial labs. It helps them overcome possible hardware challenges slowing them down, without forcing them into the costly and time-consuming process of changing the software environment they rely on.

For industrial laboratories that have felt stuck between the opportunity of new solutions and the fear of disrupting their CDS workflows, the TRACE 1600 Series GC offers a way forward.

It is time to explore a GC platform engineered for uptime and stability.

- Visit us on Gas Chromatography Systems for High Performance Workflows

- Visit us on LinkedIn: #ChemicalAnalysis #ChromatographyDataSystem #GasChromatography #Industrial

Dr. Daniela Cavagnino

Dr. Daniela Cavagnino is Product Marketing Manager for GC and Sampling Solutions. She started her career in gas chromatography at Thermo Fisher Scientific spending several years in the R&D laboratories working on GC technology innovation. Then, she conveyed her technical background into product management and marketing management roles with more than 20 years’ experience in promoting GC/GCMS technology and applications in several different market segments.