Benefits of Using Desorb Flow Control with the Encon Evolution

EST Analytical: Benefits of Using Desorb Flow Control with the Encon Evolution

Abstract

Desorb flow control was developed in order to help manage the moisture associated with the four minute desorb time required for USEPA method 524.2. An added benefit to this process is the reduction in helium consumption when using this technique. This application will explain the patented process of Desorb Flow Control (DFC) (United States Patent Office numbers: 8062905, 7951609, 7803635) for Helium conservation and moisture control.

Introduction

Helium has been an essential component in environmental testing for years. Since Helium is an inert gas with a similar diffusion speed as Hydrogen, it is ideal for using as a carrier gas in Gas Chromatography. In recent years, however, there has been an increasing shortage of Helium, leading laboratories to come up with different ways of conservation.

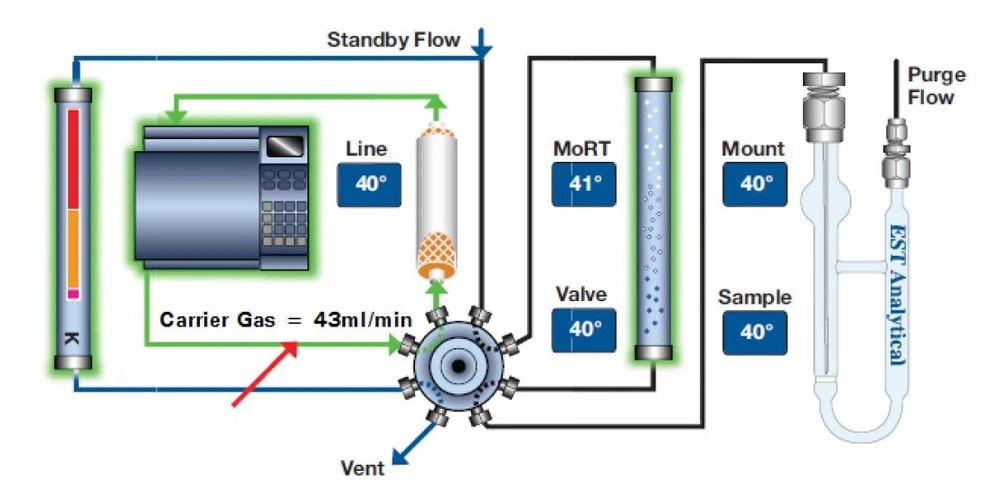

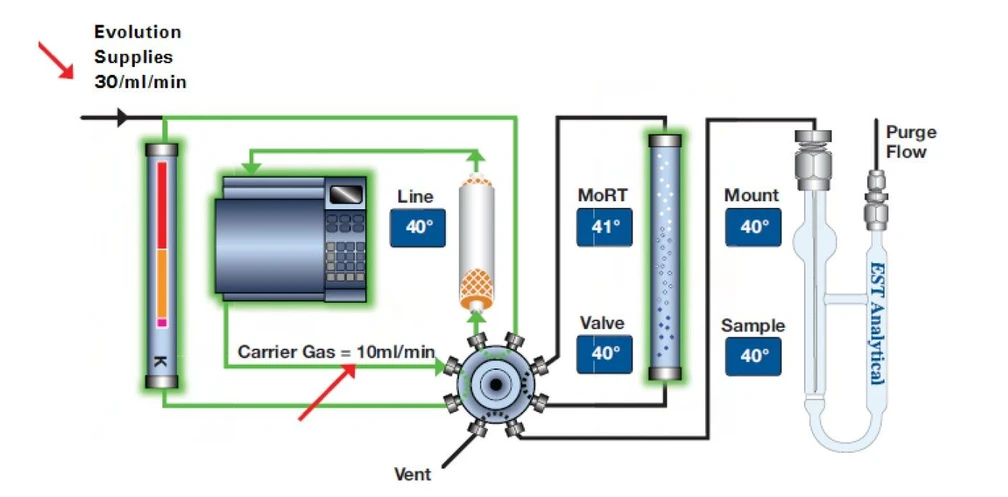

Desorb Flow Control was developed to assist laboratories routinely running for USEPA Method 524.2. Method 524.2 requires a four minute desorb and laboratories are reporting issues with water when using the long desorb time. By using DFC, labs are now able to keep the required four minute desorb time and control the amount of water transferred to the GC by decreasing the flow through the trap during desorb while maintaining the desired split ratio at the GC inlet. Subsequently, DFC not only controls the amount of water transferred, but also decreases Helium consumption. See Figures 1 and 2.

EST Analytical: Figure 1 - Traditional GC Flow

EST Analytical: Figure 1 - Traditional GC Flow

EST Analytical: Figure 2 - GC Flow with Encon Evolution using DFC

EST Analytical: Figure 2 - GC Flow with Encon Evolution using DFC

(NOTE: The Encon Evolution provides the increased flow after the trap during desorb at a set time in the desorb process.)

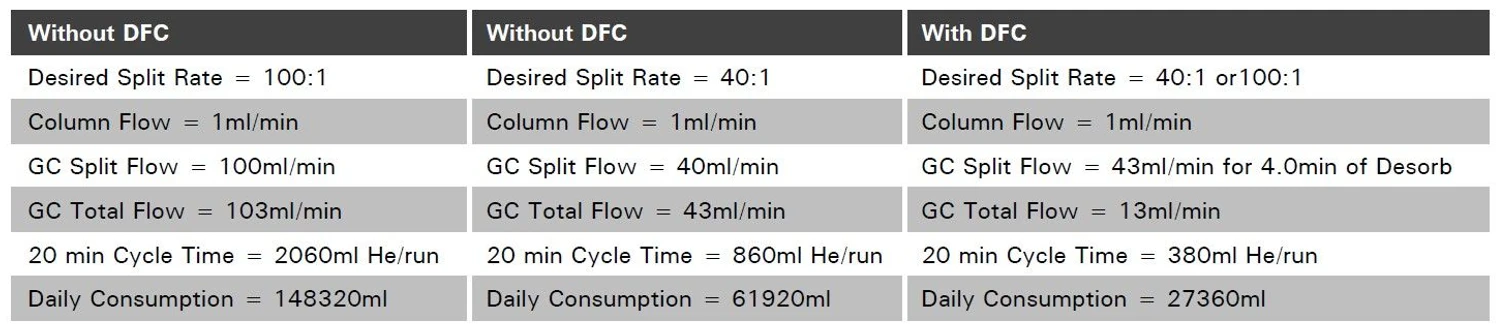

The advent of more efficient purge and trap systems and more sensitive GC/MS systems has aided in laboratories’ production. However, water control is still an issue. Labs may pass an initial calibration curve, but as water builds up in the system, internal standard response drops over time, causing the laboratory to fail continuing calibration checks. In order to combat water, many labs use a high split rate. As a consequence, Helium consumption is much higher and sensitivity is decreased. Using DFC, labs can still achieve the moisture control required thus creating a more stable system and lowering Helium consumption by as much as 80%, depending on the experimental split rate. See Table 1. *The table below assumes a throughput of 72 samples per day.

EST Analytical: Table 1 - Daily Helium Consumption

EST Analytical: Table 1 - Daily Helium Consumption

Experimental

The sampling system used for this study was the EST Analytical Encon Evolution concentrator and the Centurion WS autosampler. The concentrator was affixed with a Vocarb 3000 trap and connected to an Agilent 7890A GC and 5975C inert XL MS. The GC was configured with a Restek Rxi-624 Sil MS 30m x 0.25mm x 1.4µm column. Two different split ratios were used for comparison in this study, a 40:1 split rate was used for the baseline data and a 10:1 split rate was used for the DFC data. Experimental parameters used for this analysis are listed below.

Purge and Trap Parameters

- Concentrator: EST Encon Evolution

- Trap type: Vocarb 3000

- Valve oven temperature: 150 °C

- Transfer line temperature: 150 °C

- Trap temperature: 35 °C

- Moisture Reduction Trap (MoRT) temperature: 39 °C

- Purge time: 11 min

- Purge flow: 40 mL/min

- Dry purge Temp.: Ambient

- Dry Purge Flow: 40mL/min

- Dry Purge Time: 1.0 min

- Desorb pressure Control: ON

- Desorb Pressure: 13.5 psi

- Desorb time: 4.0 min

- Desorb preheat delay: 10 sec

- Desorb temperature: 250 °C

- MoRT bake temperature: 210 °C

- Bake temperature: 260 °C

- Sparge vessel bake temperature: 110 °C

- Bake time: 8 min

- Bake flow: 85 mL/min

Purge and Trap Auto-Sampler: EST Centurion WS

- Sample Type: Water

- Water Volume: 25ml

- Internal Standard Vol.: 5 µl

GC/MS Parameters

- System: Agilent 7890A/5975

- Inlet: Split/splitless mode, 200 °C, 40:1 and 10:1 split ratio, 7.45 psi inlet head pressure

- Column: Rxi-624Sil MS 30m x 0.25mm I.D. 1.4µm film thickness

- Oven program: 40 °C (1.5 min) → ramp 8 °C/min → 100 °C, ramp 20 °C /min to 210 °C, hold for 1.25 min, 16.5 min run time

- Column flow rate: 1 mL/min helium

- Total flow: 13.8 and 43.8 mL/min

- Source temperature: 230 °C

- Quadrupole temperature: 150 °C

- Transfer line temperature: 180 °C

- Scan range: m/z 35–300, 3.12 scans/sec

- Solvent delay: 1.0 min

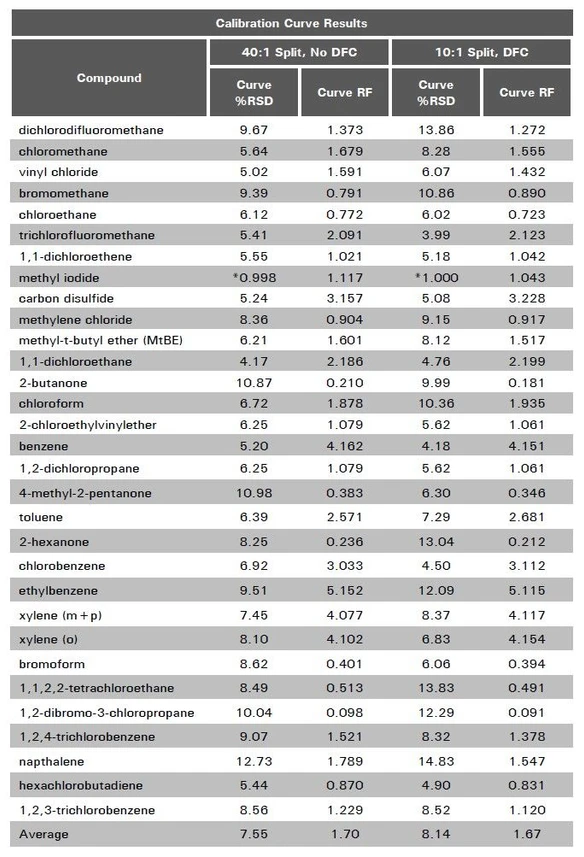

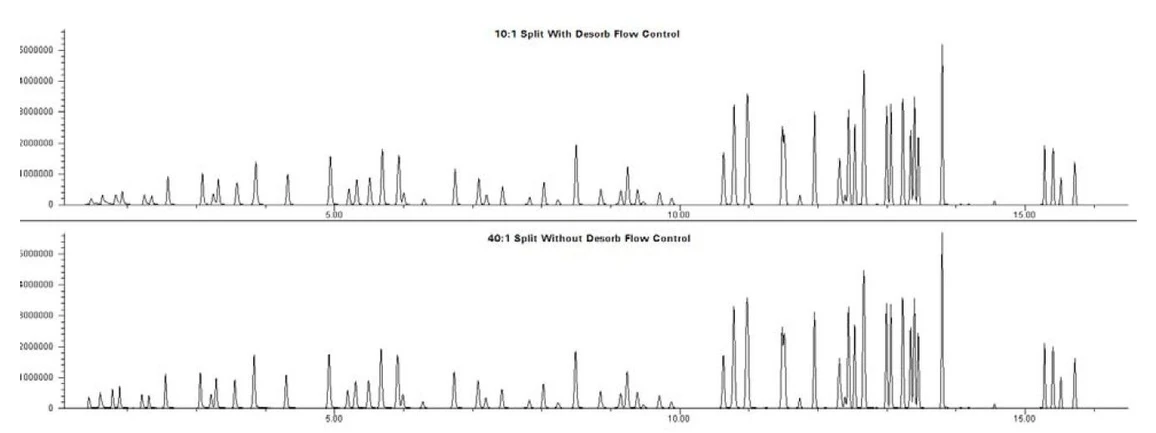

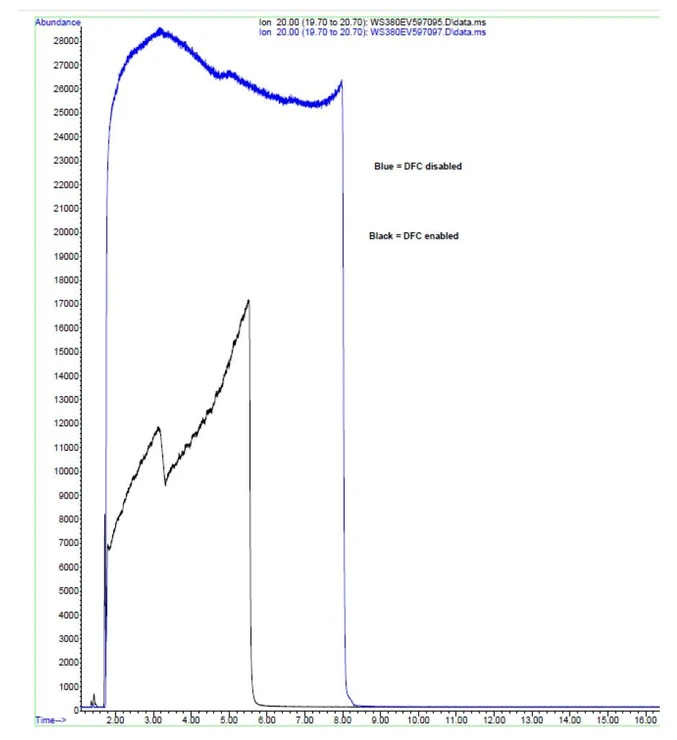

The USEPA Method 524.2 standards were acquired from AccuStandard. The linear ranges of the experiments were established by running eight point calibration curves from 0.5 to 100ppb. Table 4 displays curve linearity and compound response for the curves. Figure 3 displays chromatograms of the 20ppb calibration point with and without DFC. Finally, an experiment was run using Selective Ion Monitoring (SIM) of m/z 20 with and without DFC. This was done in order to show water control using D2O as the compound of interest so as not to SIM for water and overwhelm the MS. Figure 4 displays the results of this experiment.

EST Analytical: Table 4 - Curve Linearity and Compound Response Summary

EST Analytical: Table 4 - Curve Linearity and Compound Response Summary

EST Analytical: Figure 3 - 20ppb Chromatograms With and Without DFC

EST Analytical: Figure 3 - 20ppb Chromatograms With and Without DFC

EST Analytical: Figure 4 - Overlay of D2O mz 20 With and Without DFC

EST Analytical: Figure 4 - Overlay of D2O mz 20 With and Without DFC

Conclusions

The results of this study show the patented Desorb Flow Control is an exceptional tool for conserving helium and creating a more stable system. The option of maintaining the desired split ratio at the GC inlet while decreasing the flow through the trap during desorb provides sensitivity while controlling the amount of moisture being sent onto the GC column. Furthermore, the split rate during the GC/MS run time is substantially lower than during the desorb time. Laboratories can have the advantage of running a higher split rate during the desorb process then maintaining a lower split during the rest of the GC/MS separation and analysis, thus providing laboratories with up to an 80% reduction in GC/MS helium use.