News from LabRulezGCMS Library - Week 33, 2025

LabRulez: News from LabRulezGCMS Library - Week 33, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 11th August 2025? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you poster by Agilent Technologies / ASMS, application note by Shimadzu and technical note by Thermo Fisher Scientific!

1. Agilent Technologies / ASMS: Fully Automated Workflow for Volatile PFAS Analysis in Food Contact Materials Using GC-Triple Quadrupole

- Poster

- Full PDF for download

The analysis of per- and polyfluoroalkyl substances (PFAS) in food contact materials (FCMs) is crucial due to potential health and environmental concerns. Increased PFAS testing is needed to meet public demands and new regulations. Gas Chromatography coupled with Triple Quadrupole Mass Spectrometry (GC/TQ) offers a robust and sensitive method for detecting volatile PFAS. However, manual sample preparation could pose a bottleneck, impacting lab productivity. This study presents a robust and fully automated method using the PAL3 platform with GC/TQ for quantifying more than 30 volatile PFAS in FCMs, such as paper coffee cups. The automation approach minimizes human error, improving reliability and reproducibility for routine analysis and safety assessments of PFAS in FCMs.

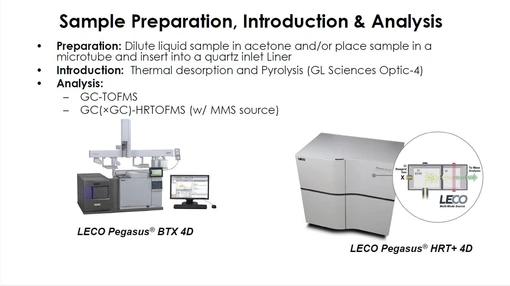

Experimental

Automated Sample Preparation

The integrated 120 cm PAL3 Series 2 RTC autosampler, paired with the Agilent 7010D GC/TQ, facilitated a fully automated PFAS quantitation workflow using a paper cup matrix. It served as an automated liquid handling platform for preparing calibration standards, extracting samples, and injecting them into the GC/TQ system, equipped with essential tools and modules.

GCMS Instrumentation

The 7010D GC/TQ with HES 2.0 ion source was coupled to an Agilent 8890 GC system equipped with an MMI inlet and splitless liner (p/n 5190-2293). SWARM autotune optimized the instrument settings. The Agilent 8890 GC, operated in pulsed splitless mode with a splitless inlet liner, was used for analysis. The PAL3-GC/TQ system, managed by MassHunter Acquisition 13.0 software, provided an integrated single-software experience. MassHunter Optimizer was used to obtain MRM transitions for 34 targets, along with collision energies1 . Instrument operating conditions and parameters are given in the table below

Conclusions

- This study demonstrated a robust, fully automated method for analyzing volatile PFAS in FCMs using the PAL3 Series 2 RTC autosampler and Agilent 7010D GC/TQ system.

- Method detection limits (MDL), linearity, retention time (RT) precision, area precision, and QC recovery was performed to assess the workflow performance.

- The MassHunter Optimizer simplified method development, while the HES 2.0 ion source provided exceptional sensitivity, achieving sub-ppb MDLs.

- For all FTOHs, an LOQ of 20 μg/kg with recoveries of 65% to 135% and %RSD < 10% were achieved, highlighting the high extraction efficiency, accuracy and reliability of the automated workflow.

- Automation reduces human errors, decreases chemical usage, and enhances productivity, offering reliable trace-level volatile PFAS monitoring in FCMs for regulatory guidance.

2. Shimadzu: Analysis of Benzene and Toluene by Brevis GC-2050 Using ASTM D3606

- Application note

- Full PDF for download

User Benefits

- Quantitation of benzene and toluene in fuels based on ASTM D3606 is possible.

- Highly accurate backflush analysis is possible by using the SMI flow device.

- The compact design of the Brevis GC-2050 enables space-saving in the laboratory.

Benzene and toluene are widely used as feedstocks for chemical products, but due to concerns about their effects on human health, the permissible concentrations of these two compounds are specified in various regulations. ASTM D3606 1) provides two quantification methods (Procedures A and B) for benzene and toluene in automotive fuels. The corresponding concentrations of benzene and toluene are 0.12-5.2 Vol% and 0.4-19.7 Vol% when using Procedure A and 0.10-5.0 Vol% and 2.0-20.0 Vol% when using Procedure B. In this Application News article, benzene and toluene were quantified by Procedure A in ASTM D3606. Satisfactory linearity of the calibration curves and reproducibility of the quantitation values could be obtained for both compounds.

System Configuration and Analysis Conditions

Table 1 shows the system configuration and analysis conditions. The compact Brevis GC-2050, with a width of about 35 cm, can contribute to space-saving in the laboratory while also demonstrating high analytical performance. In procedure A, benzene and toluene are measured with a backflush system using a capillary column. Backflush has the advantage of shortening the analysis time. Fig. 1 shows a schematic diagram of the backflush system. In addition to the FID detector (FID1) connected to the Wax analytical column, a second FID detector (FID2) which is connected to the restrictor tube, is used for monitoring to determine the timing of backflushing. The gas that flows through the columns is supplied from the injection port (SPL) and digital flow controller (AUX-APC). This is connected to discs called an SMI Flow Disc and 2-DET Splitter, which are used to split the flow to the two detectors. The SMI Flow Disc is a flow device for capillary analysis, and has the features of minimal leakage, a low dead volume, a low heat capacity, and inertness. For this reason, the device has the advantages that the temperature inside the device easily follows the temperature of the column oven, and it is also possible to analyze components with high adsorptivity. Before backflushing, the SPL pressure is set high, and during the backflush operation, the gas in the pre-column is made to flow in the reverse direction (backflushed) by changing the pressures of the SPL and AUX-APC. In this experiment, the initial backflush time was set to 3.1 min to match the elution time of toluene (Fig. 2).

Conclusion

Using the Brevis GC-2050, an analysis of benzene and toluene as specified in ASTM D3606 was conducted. The analysis time could be shortened by using a backflush system. As the quantitation values of benzene and toluene were within the standard range for both reproducibility and repeatability, satisfactory results were obtained.

3. Thermo Fisher Scientific: How NeverVent technology enables consistent uptime for continued lab operation

- Technical note

- Full PDF for download

Benefit summary

- Eliminates unnecessary downtime

- Maintains productivity

- Simplifies maintenance

- Enables disruption-free ionization type change

- Increases ROI

What is NeverVent technology and how does it work?

Thermo Scientific™ NeverVent ™ technology is unique to Thermo Fisher Scientific’s GC-MS products. It allows for routine maintenance, exchange of ionization mode, and direct probe work to be performed without the need to break the vacuum of the mass spectrometer:

- Removing/replacing the ionization source: Utilizing the vacuum probe interlock (VPI) in combination with an isolation valve, the ionization source can be removed the from the system without venting the MS. The source can either be cleaned or replaced with a spare clean source, and samples can be run without long stabilization times which would be required if the system was vented.

- Changing ionization type: Using the VPI, the ionization source can be replaced with a different type of ionization source, for example, switching from Electron Ionization (EI) to Chemical ionization (CI) within a few minutes.

- Using direct sampling probes: The VPI also allows the use of direct probes on some NeverVent GC-MS systems. This enables direct sampling into the MS system, bypassing the GC separation, and is useful in compound characterization and when analyzing very difficult to volatilize samples like oils or metal complexes.

- Changing the GC column without venting: When performing common column maintenance like trimming, or replacing the column entirely, the V-Lock Source Plug allows the MS to be sealed off from inside the manifold. Columns can be exchanged or maintained without ever breaking vacuum.

What are the benefits to NeverVent technology?

NeverVent technology allows a significant increase in instrument uptime. On a traditional GC-MS when performing maintenance, such as ionization source cleaning or column exchange, the MS must be vented. Venting the MS introduces air and moisture into the system. Once the maintenance is performed, the system is then pumped back down to vacuum and a stabilization period is required to ensure air and moisture are evacuated from the system. This process often takes overnight to complete and means samples cannot be run until the following day.

Due to the unique design of a NeverVent GC-MS system, the vacuum is maintained which means samples can be run shortly after the maintenance is performed. This could be the difference betwen running a batch of samples overnight or waiting for a system to be ready to run. Utilizing NeverVent technology eliminates unnecessary instrument downtime due to venting the systems during maintenance, thus increasing productivity. Figure 2 highlights the time savings that can be achieved with NeverVent technology.

For a typical GC-MS system where maintenance on the source is performed every three months, NeverVent technology can give you an extra four days of operation per year. When adding in column and ionization mode changings, the productivity gains are even more significant.