News from LabRulezGCMS Library - Week 21, 2025

LabRulez: News from LabRulezGCMS Library - Week 21, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 19th May 2025? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you application notes by Agilent Technologies, Shimadzu, poster by MDCW and technical note by Thermo Fisher Scientific!

1. Agilent Technologies: Py-GC/MS/MS Microplastic Analysis of Samples Containing Interfering Substances

- Application note

- Full PDF for download

Microplastics, defined as plastic fragments with a particle size of 5 mm or less, originate from various products, such as cosmetics, clothing, food packaging, and plastic waste. Microplastics have been detected in water, soil, and air environments,5 as well as in food and within living organisms.7 Consequently, numerous analytical techniques are being developed to investigate the extent of microplastic contamination and its impacts.

Microplastics can be seen with the naked eye or a microscope when the particle size is large, but observation is difficult when the size is small, and quantitative analysis by type of plastic is difficult. Techniques using spectroscopic instruments, such as IR or Raman, or thermal analysis instruments such as Py-GC/MS or thermal extraction desorption (TED)-GC/MS have been widely used.1, 2, 3, 4 IR and Raman spectroscopy can be used to identify the type, shape, size, and count of microplastics on filters after sample preparation and filtration. These techniques rely on spectroscopic analysis of the microplastics retained on the filter. For Py-GC/MS or TED-GC/MS, the microplastics collected on the filter are thermally decomposed, and the resulting compounds are analyzed with GC/MS, allowing for the quantification of each type of microplastic8 (by weight). In particular, Py-GC/MS has recently been recognized as an ASTM International method11 and is widely applied as an analytical method for analyzing microplastics in drinking water.12 In the case of environmental samples or food samples with complex matrices, additional matrix effects can negatively impact analytical performance or result in thermal decomposition products that cannot be separated from microplastic thermal decomposition product peaks, causing interference and overlapping with target ions.6

In this application, we applied Py-GC/MS/MS (MRM mode) to microplastic analysis to determine whether accurate quantitative analysis of microplastics is possible even in samples containing complex matrices.

Instrument and analysis conditions

The instruments used were a Frontier Lab pyrolyzer (Py-3030D) and an Agilent 8890 GC coupled to a 7000E triple quadrupole GC/MS system. The temperature of the pyrolyzer was set to 600 °C, as shown in Table 1, and the components produced by thermal decomposition were passed through the GC inlet (320 °C, split 50:1), cryo-focused by liquid nitrogen applied to the front end of deactivated metal capillary column (UA-5, 30 m x 0.25 mm x 0.25 µm) in the Microjet Cryo Trap, separated by the GC oven temperature program after about 3 minutes, and transferred to the mass spectrometer. The analysis conditions are shown in Tables 1, 2, 3, and 4.

Results and discussion

Chromatogram

Chromatograms resulting from the analysis of the microplastics calibration standard (MPCS) that includes 11 types of microplastics are shown in Figure 1 for both Scan and MRM modes. The Scan mode total ion chromatogram (TIC) can be processed into extracted ion chromatograms (EIC) to confirm the target ion (m/z) for each indicator peak, as seen on the left side of Figure 1. The MRM TIC and EIC are shown on the right side of Figure 1. As can be seen, MRM mode can reduce matrix interference and enhance selectivity. Calibration curves can be created using either Scan or MRM mode using concentration of the MPCS.

Conclusion

We have established a quantitative analysis method using Py-GC/MS/MS (MRM mode) for complex matrix samples and trace levels of microplastics.

Under the established Py-GC/MS/MS (MRM mode) conditions, the linearity of the calibration curves generated for the 11 types of microplastics, ranging from several hundred ng to several µg, was excellent (R² > 0.99). Compared to Scan (Target EIC) mode, noise is reduced by two to several times when analyzed in MRM mode, and accordingly, the S/N ratio is increased when analyzed in MRM mode, enabling the detection of microplastics with better selectivity. In addition, when there is matrix interference during sample analysis, more accurate quantitative results can be obtained by applying the MRM mode, and Py-GC/MS/MS (MRM mode) can be very useful for quantifying complex matrix samples and trace levels of microplastics.

2. MDCW: Analysis of (micro-)plastic-associated chemicals released into marine environments by comprehensive multidimensional gas chromatography-mass spectrometry

- Poster

- Full PDF for download

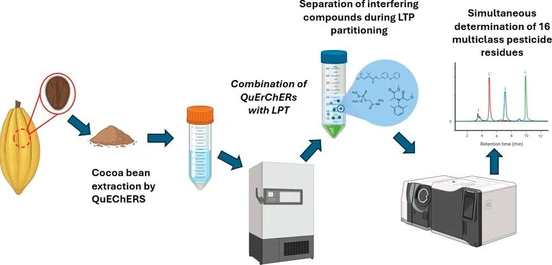

Plastic materials contain many different chemicals, which include functional additives as well as trace levels of non-intentionally added substances. Plastic released into the environment acts as a vector for these chemicals, which may cause harm to exposed organisms. The complex mixture of chemical classes and concentrations within plastics is a challenge for analysis, which can be addressed through the use of multidimensional analytical approaches.

Here, the chemical composition of different polymer samples was analysed using comprehensive multidimensional gas chromatography coupled to time-of-flight mass spectrometry. Ultrasonication assisted extractions with solvent represents a ‘worse-case-scenario’ in relation to environmental leaching, and provides a starting point for non-target analysis of microplastic leaching in marine environments.

Results

All the virgin polymer samples released chemicals under organic extraction. As shown in Figure 1, the Hexane DCM:MeOH MeOH EtOAc number of compounds released by each polymer was influenced by the solvent used for the extraction. Additionally, the conventional polymers released a higher number of chemicals than the biopolymers, particularly LDPE and PP.

The high number of compounds released by LDPE and PP is due to the release of polymer-derived alkanes. The use of GC ×GC enabled separation and identification of other plastic-associated compounds from the alkane series (see respective chromatograms). In contrast, the other polymers released a range of compound classes. Some of the compounds identified in the extracts, for example phthalates, are detrimental to both human and environmental health.

Conclusion

Chemical extracts from several polymer samples demonstrated that virgin polymer samples contain chemicals which are not chemically bonded to the bulk polymer material – and therefore have potential to be released into the environment. Future leaching studies can be informed by the chemical identifications made, and increase the confidence that those compounds identified in leachates did originate from the respective polymer.

3. Shimadzu: Quantitative Analysis of Furan and Alkylfuran in Processed Food Using a Triple Quadrupole GC-MS System and an SPME Arrow

- Application note

- Full PDF for download

User Benefits:

- Using an SPME Arrow allows for highly sensitive analysis of furan and alkylfuran in processed food.

- The MRM mode enables highly reliable analysis even in complex matrices.

- An AOC-6000 Plus autosampler helps increase productivity and repeatability through automated pretreatment.

Furan and alkylfuran compounds are commonly found in many foods, including coffee. They are known as volatile organic compounds that contribute to aroma. However, recent studies in various countries have reported health concerns regarding these compounds and monitoring of furan and alkylfuran has been recommended in the EU1) .

These compounds are frequently measured using the HSGC/MS method, which is convenient and effective when present at relatively high concentrations. However, for samples containing low concentrations, pretreatment for concentration is necessary. This Application News article describes a method using an SPME Arrow and GC-MS/MS system that enables more consistent analysis even at trace concentrations in complex matrix samples.

Instrument Configuration and Analytical Conditions

The analysis was performed using an AOC-6000 Plus multifunctional autosampler and a GCMS-TQ8040 NX triple quadrupole gas chromatograph mass spectrometer system (Fig. 1). The AOC-6000 Plus is a multifunctional autosampler that can automatically switch between various sample injection methods, such as liquid injection, headspace injection, and solid-phase microextraction (SPME), depending on the sample and purpose (Fig. 2). In this analysis, an SPME Arrow, which offers improved durability compared to a traditional SPME fiber, was used forsample analysis. When using sampling methods involving concentration, such as the SPME method, matrix-derived impurities may also be concentrated, making it difficult to improve sensitivity due to interference from impurities. In this analysis, high sensitivity for analyzing furan in processed foods was achieved by using the SPME method in combination with the MRM mode of the triple quadrupole GC-MS system.

Comparison of SIM and MRM

To confirm the improvement in selectivity with MRM, analysis using the SIM mode was also conducted. Generally, the MRM mode of a triple quadrupole GC-MS system offers better selectivity compared to the SIM mode, leading to higher sensitivity and more consistent detection. Fig. 5 shows the SIM and MRM chromatograms of four components detected in baby food. While each component was detectable with both modes, the MRM mode provided higher selectivity, whereas the SIM mode was more susceptible to interference from impurities. Therefore, manual peak integration or changes to the quantitative ions may be required in the SIM mode depending on the sample.

Conclusion

Quantitative analysis of furan and alkylfuran in processed food was conducted using an SPME Arrow and a triple quadrupole GC-MS system. The AOC-6000 Plus multifunctional autosampler allows for highly sensitive and reproducible quantification of furan compounds using the SPME Arrow method. Additionally, by enhancing selectivity with the MRM mode of the triple quadrupole GC-MS system, more reliable analytical results were obtained.

4. Thermo Fisher Scientific: Data-driven GC and GC-MS instrument monitoring with SmartStatus intelligent software

- Technical note

- Full PDF for download

Rising costs can significantly impact an analytical laboratory’s profit margin, and it is crucial to maintain productivity and ensure maximum asset utilization to stay competitive. To balance increased overhead costs, including analytical gases and staff pay, laboratories must ensure that analytical instrumentation consistently produces results, without interruption. Re-analyzing entire runs due to drops in sensitivity, unnecessary downtime, and underutilization of consumables is expensive and time consuming.

Thermo Scientific™ SmartStatus™ instrument tracking can help laboratories realize additional cost savings. This is done by using data-driven insights to accurately determine when to perform maintenance and replace consumables and parts, so that the system consistently runs smoothly for all samples and meets specifications in the initial analysis. This ensures that consumables and parts are replaced on the correct schedule and avoids excess instrument downtime.

SmartStatus instrument tracking is an intelligent instrument health software that allows users to track key aspects of their GC-MS system. It is available as standard on the Thermo Scientific™ TRACE™ 1600 GC series, Thermo Scientific™ AI/AS 1610 liquid autosampler, Thermo Scientific™ ISQ™ 7610 GC-MS series, and the Thermo Scientific™ TSQ™ 9610 GC-MS/MS series. In this technical note, the new SmartStatus instrument tracking capabilities are highlighted with examples of how it can enable analytical laboratories to keep instruments producing consistent results.

SmartStatus software overview

SmartStatus intelligent software, available within Thermo Scientific™ Chromeleon™ Chromatography Data System (CDS), allows monitoring of the entire analytical system including Thermo Scientific™ autosamplers, GC, GC detectors (FID and TCD), and mass spectrometers (MS). Hundreds of key instrument parameters are monitored by SmartStatus software, which provides real-time data and insights informing the user to potential problems before they arise to ensure maximum instrument uptime. This allows users to make informed decisions on which parts of the analytical system require attention and when. By performing preventative maintenance using data-driven guidance, optimal instrument performance is sustained day in and day out. Figure 1 shows the SmartStatus software overview page for a TSQ 9610 triple quadrupole MS coupled to a TRACE 1610 GC and AI/AS 1610 liquid autosampler. This overview page allows a user to quickly determine if the system is ready to run or requires attention.

For more information on instrument status, there is a detailed view for each part of the system. This next level view shows how many injections have been performed for the various GC consumables, the lifetime of the MS detector and filament, and when the last tune was performed. Figure 2 shows an example of the GC and MS parameters and how they are monitored. Each parameter is represented as a counter gauge. As the usage increases, the gauge changes color to quickly notify the user of any maintenance that is required or will be needed soon. This allows users to plan maintenance in advance to fit it around their schedule and workload. SmartStatus instrument tracking can be monitored directly in Chromeleon CDS, and consumables usage can also be monitored directly on the TRACE 1610 GC touch screen through the dedicated instrument health icon, as shown in Figure 3.

Conclusion

SmartStatus software is intelligent and data-driven, allowing users to make informed decisions on when to perform maintenance on their GC and GC-MS systems. Its features and advantages include:

- At-a-glance system ready status allowing the analyst to act only when needed, removing wastes

- User customizability of monitored parameters, threshold, and time units, which gives users control to monitor the system in a way that fits their needs

- Intelligent preventative maintenance alerts ensuring maintenance to be performed before issues arise, keeping the instrument up and running longer

- Consumable tracking that enables sustainable operation and maximization of the use of each consumable

- Smart Support for rapid remote diagnosis to ensure any instrument issues can be resolved without delay

Utilizing SmartStatus software on the TRACE 1600 series GC, TSQ 9610 GC-MS/MS, and ISQ 7610 GC-MS gives the analyst data-driven insights to make informed decisions that allow laboratories to operate more sustainably by maintain productivity, maximizing consumable usage, and reducing laboratory costs.