How to clean laboratory water: Practical tips and solutions to the most common problems

Watrex: How to clean laboratory water: Practical tips and solutions to the most common problems

Virtually no laboratory today can do without a source of purified water. The amount produced and the required purity depend on a number of factors, but it is always true that we expect stable performance and reliable function from water treatment equipment.

While distillation apparatuses used to dominate, today a combination of flow purification techniques is usually used to prepare purified water for laboratories, the specific list of which depends primarily on the required final water purity. These include filtration, adsorption, removal of dissolved substances by reverse osmosis, deionization (using ion exchangers or electrochemically), photooxidation, sterilization by UV radiation and, last but not least, ultrafiltration.

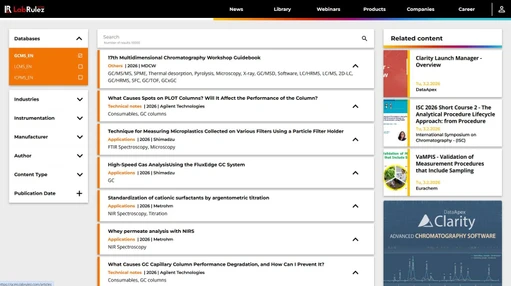

Overview of Watrex water systems

In addition, modern devices often allow continuous monitoring of water quality in real time, which significantly increases control over the process. However, a number of complications can still occur - and that is why RNDr. Roman Kysilka from Watrex Praha provides an overview of the basic principles of proper operation and advice on how to recognize and solve the most common

problems (Troubleshooting).

How to operate a water treatment plant in a laboratory without problems

There are certain common principles that apply to the use of all equipment for the preparation of purified water. The most important ones are summarized in the following points:

- Recommendations before purchasing equipment - choose a model with a slight power reserve that produces water of the quality you need. The purer the water, the higher the operating costs. Use water purified by special procedures only where necessary.

- Develop a maintenance plan for your equipment and its documentation. Designate a person responsible for the operation of the equipment. For low-use and basic equipment (e.g. reverse osmosis systems), annual periodic maintenance is sufficient, while for critical applications, daily water quality checks may be necessary. Establish an operating logbook, or at least record the checks and maintenance on a label placed on the equipment.

- All models of devices for preparing purified water from tap water contain filters that remove suspended solids. Depending on the degree of contamination of the water from the water supply and the volume of treated water, the replacement period varies considerably. The replacement period for a specific installation is usually recommended by the supplier, but it is advisable to perform a simple visual inspection. A contaminated filter is easy to identify.

- If a reverse osmosis (RO) membrane is used in the device, attention should be paid to its proper functioning. The service life of the RO membrane is several years with proper maintenance of the protective filters. If the device is not equipped with a reverse osmosis process efficiency measurement, it is advisable to check the performance, efficiency and yield of this purification stage at least once a year.

- To achieve a low content of dissociated compounds (ions), filters filled with an equimolar mixture of cation and anion are most often used. More modern devices alternatively use electrodeionization. If the device includes a deionization stage, it should always be equipped with a conductivity measurement of the produced water, or at least an indication of exceeding the limit value of specific conductivity. In daily use, it is advisable to check the conductivity at least once a day, in other cases at each first sampling.

- Most devices for the preparation of purified water are not sterile and are populated to varying degrees by microorganisms, which is usually accompanied by a higher value of organically bound carbon (TOC) in the water. This may not be a problem for basic laboratory applications, but if we require water that is sufficiently pure for HPLC, work with tissue cultures, molecular genetic experiments, and the like, the device must include technology to minimize the impact of organisms. This includes the inclusion of UV radiation sterilization sources, the application of ozone generated by UV emitters at 184 nm, microfiltration and ultrafiltration. For proper function, it is important to adhere to the component replacement interval recommended by the device manufacturer (either in terms of time or according to the volume of treated water) for all these techniques. Otherwise, a malfunctioning purification stage is often discovered only on the basis of false experiment results.

- All types of equipment should be periodically (once a year, once every two years - depending on the intensity of use and the potential risk of endangering the experiments) verified whether they meet the parameters expected of them. For systems with their own measurement, it is necessary to check whether the measurement results of the built-in sensors provide valid values.

Watrex: Fig. 2: Illustrative image of possible consumables used in some water systems.

Watrex: Fig. 2: Illustrative image of possible consumables used in some water systems.

Troubleshooting

Even with careful maintenance and following operating recommendations, there may be times when your water treatment equipment does not function as expected or shows signs of a problem. Below are tips for identifying and resolving some common problems. Before you begin any work on your equipment, make sure you understand its function and, if necessary, consult the manual provided by the manufacturer (perhaps as a first step).

1. Basic Check

Before you start looking for more complex causes, perform the following basic checks:

- Power and Water Supply: Check that the equipment is properly connected to the electrical network and that it is actually receiving electricity. Verify that the main water inlet valve is open and that the inlet water pressure meets the requirements of the equipment.

- Visual Check: Inspect the equipment for visible water leaks, loose or damaged hoses and connections. Check that filter covers or other parts are not visibly damaged.

- Indicators on the device: Pay attention to any status lights, displays, or alarms. Many devices indicate specific problems (e.g., filter replacement required, low pressure, poor water quality) using codes or symbols. Refer to the manual for the meaning of these indications.

- Logbook/Maintenance Records: Refer to the logbook or maintenance label. When was the last maintenance performed? Have any components been changed recently? This information may help identify the cause of the problem.

2. Specific Problems and Possible Solutions

- Low or no flow of purified water:

- Possible cause: Clogged pre-filter (mechanical filter). Low inlet water pressure. Closed valve in the system. Pump problem (if included in the system). Heavily clogged or damaged RO membrane. Clogged final (sterile) filter.

- Possible solution: Check and replace pre-filter (visual inspection as mentioned above). Verify inlet water pressure. Go through all valves and make sure they are in the correct position. Verify pump function according to manual. Check RO membrane performance (if possible, see previous text) – may require replacement. Replace final filter.

- Insufficient water quality (High conductivity):

- Possible cause: Deionization cartridge (ion exchanger) capacity exhausted. Reduced RO membrane efficiency (insufficient ion removal). Problem with electrodeionization (EDI) module. Conductivity measuring sensor failure or error.

- Possible solution: Check conductivity value on display or indicator (as mentioned in previous text). If value is out of limit, replace deionization cartridge(s). Verify RO stage efficiency (by measuring conductivity before and after RO membrane, if system allows). Verify EDI module function according to manual (may require service). Consider checking/calibrating measuring sensor (usually performed by service technician).

- Increased TOC (Total Organic Carbon) or suspected microbial contamination:

- Possible cause: Inoperative or old UV lamp (184 nm for TOC oxidation, 254 nm for sterilization). Exhausted or damaged final filter (ultrafilter, microfilter). Biofilm formation in the system, piping or tank (if used). High levels of organics or microorganisms in the inlet water.

- Possible solution: Check the operating hours or installation date of the UV lamp and replace it if it has exceeded the recommended life (according to the maintenance schedule). Replace the final filter. Sanitize the system according to the manufacturer’s recommendations (may include chemical cleaning or hot water flushing). Consider installing additional inlet water pretreatment if it is consistently poor.

- Water leaks from the system:

- Possible cause: Loose fittings or hose connections. Damaged seal (e.g. at the filter housing). Cracked filter housing or other component (e.g. due to frost or mechanical damage). Too high water pressure in the system.

- Possible solution: Immediately shut off the water supply and disconnect the appliance from the electricity supply. Carefully locate the leak. Carefully tighten the relevant fitting or connection (do not overtighten, as this may damage the thread). If the seal or component is damaged, it must be replaced with an original spare part. Check the inlet water pressure and the function of the pressure reducing valve (if installed).

- The appliance reports an alarm or warning:

- Possible cause: The system has detected a specific operating deviation or the need for maintenance.

- Possible solution: Always follow the instructions in the manufacturer’s manual for the specific alarm code or symbol. This may indicate the need to replace consumables (filter, cartridge, UV lamp), low/high pressure warning, poor water quality, internal error or the need to perform sanitation. If the steps in the manual do not resolve the problem, contact the service.

3. When to Contact Service Support

Although many common problems can be solved by yourself based on this manual and the device manual, in some cases it is necessary to contact an authorized service center or supplier:

- If the basic troubleshooting steps have failed.

- If the problem recurs even after performing the recommended steps.

- If any major water leakage that cannot be easily stopped and repaired.

- If the device reports serious error codes that are not described in the user manual.

- If it is necessary to replace key components such as the RO membrane, EDI module, pump, or main control unit.

- For regular validation and calibration of measuring sensors (conductivity, resistance, TOC), as mentioned in the previous text.

- If you are unsure of the cause of the problem or the correct repair procedure. Incompetent intervention may lead to further damage to the device or affect the quality of the produced water.

Watrex: Fig.3: Watrex Praha offers comprehensive support – from the supply of water systems and consumables to professional service.

Watrex: Fig.3: Watrex Praha offers comprehensive support – from the supply of water systems and consumables to professional service.

Remember: The best way to prevent most problems is to strictly adhere to the maintenance plan, timely replacement of consumables (filters, cartridges, UV lamps) and regular monitoring of the quality of the produced water, as described in the previous recommendations. Keeping a careful operating logbook can significantly facilitate diagnostics in the event of any problems.

Watrex Praha offers you comprehensive support in this regard – from the supply of water systems and consumables to professional service. We will be happy to help you choose the most suitable solution and will also ensure the care of your existing equipment. Leave the worries about water to us – you can focus on your work.