Advancing characterization of pyrolysis products: Comprehensive gas chromatography methods for analytes in gas and liquid phases

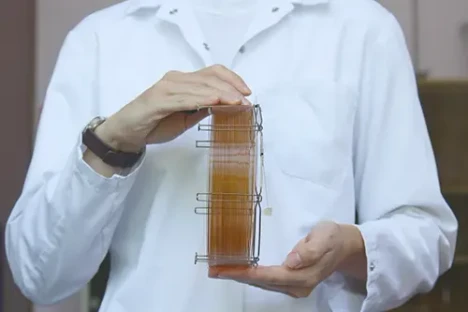

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 2. Diagram of the simultaneous GC for liquid product analysis.

The advancement of biofuel technologies relies on accurate identification and quantification of pyrolysis products. This study develops and validates gas chromatography methods that utilize multiple detectors to efficiently analyze both gas and liquid phase products in a single, rapid run with minimal sample preparation.

For gas-phase analysis, flame ionization and thermal conductivity detectors ensured precise quantification of organic and inorganic gases, achieving <1% error. A method for liquid-phase hydrocarbons and fatty acids was developed without derivatization, using mass spectrometry for identification and flame ionization detection for quantification. Validation against established methods confirmed accuracy while reducing analysis time, making these methods valuable for improving biofuel production technologies.

The original article

Advancing characterization of pyrolysis products: Comprehensive gas chromatography methods for analytes in gas and liquid phases

Bernardo A. Souto, Bingxin Hai, Justice Asomaning, David C. Bressler

Journal of Chromatography A, Volume 1741, 25 January 2025, 465641

https://doi.org/10.1016/j.chroma.2024.465641

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

1. Introduction

Given the gaps in current energy transition technologies to meet the Paris Agreement's goal of limiting global temperature rise to 1.5 °C, there is a need to develop biomass conversion technologies for biofuel production as alternative energy sources. Pyrolysis is an industrially realized thermal decomposition process conducted in the absence of oxygen and can be used to convert diverse biomass feedstocks [1,2]. Natural sources of triacylglycerols, such as vegetable oils, have been popular feedstocks for pyrolysis because their long tails of hydrocarbons mimic the structure of hydrocarbon fuel. More importantly, pyrolysis of triacylglycerols generates products similar to fossil-based fuel. The process is especially promising in areas where the hydroprocessing industry is well established because the technology is very similar to that of conventional petroleum refining [3]. To assist in lipid pyrolysis development, accurate quantification and identification of the compounds in the fuel, along with verification of mass balance, are essential as chemical composition determines fuel properties.

Lipid pyrolysis typically produces liquids, solids, and non-condensable gases, which can be a product of interest depending on their composition. Analyzing the gas products, for instance, can be a challenging process due to the nature of the sample, usually comprising of fixed gases, such as carbon monoxide and dioxide, nitrogen, and hydrocarbons [4]. Very few studies have reported the quantification and identification of the gas product [[5], [6], [7]]. In these studies, gas chromatography coupled with a flame ionization detector (GC-FID) or a thermal conductivity detector (GC-TCD) is commonly employed, where FID detects light hydrocarbons and TCD is used for inorganic gases. To the best of the authors’ knowledge, it remains unclear whether these studies applied simultaneous detectors or not.

One of the major products from pyrolysis is the liquid product, for which the most commonly used method is gas chromatography coupled with a mass spectrometer (GC–MS) or a flame ionization detector (GC-FID) [[8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21]]. Some studies have carried out analysis with both detectors, using GC–MS for compound identification and GC-FID for compound quantification [[22], [23], [24], [25], [26], [27]]. The FID is often selected because of its low purchase and running costs, high sensitivity to hydrocarbons, and linear response that is proportional to the number of carbon atoms in a hydrocarbon molecule, making it more reliable for determining the quantity of hydrocarbons [28,29].

As mentioned above, while there are numerous studies reporting the composition of pyrolytic products, the majority of these studies employed area normalization or quantification of certain compound classes. Thus, these results may not represent the accurate composition of pyrolytic products. To our best knowledge, no comprehensive method addressing simultaneous hydrocarbon and fatty acid characterization of pyrolytic product without derivatization has been previously reported. The aim of this study was to develop and validate an accurate method for simultaneous identification and quantification of organic and inorganic compounds in the gas phase, as well as hydrocarbons and fatty acids in the liquid phase generated from pyrolysis, without the need for fatty acid derivatization. This method accounts for all GC identifiable peaks and achieves accurate quantification. It is deemed to be a time-saving approach and applicable to pyrolysis products derived from any lipid feedstock.

2 Materials and methods

2.1.1 Simultaneous gas chromatography-thermal conductivity and flame ionization detectors

A custom PerkinElmer 590 GC equipped with thermal conductivity (TCD), flame ionization (FID) detectors, three automatic valves, and a manual sample purge valve was used for gas product analysis. This configuration allowed for the simultaneous analysis of light hydrocarbon gases (ranging from C1 to C4) using FID and fixed gases (hydrogen, carbon monoxide, carbon dioxide, nitrogen, and oxygen) using TCD. The automatic valves were set in an external oven at 150 °C, where 5 mL of a gas sample could be injected and split between the FID and TCD columns. Fig. 1 depicts the system configuration in its ready state, where all automatic valves are in the off position. The oven program was established for both columns, starting at 60 °C and holding for 8.5 min, then ramping to 200 °C at 10 °C/min and holding for 1 min, resulting in a total run time of 23.5 min.

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 1. Diagram of the simultaneous GC for gas product analysis. Configuration for gas sampling, where all valves are in the off position. Green lines represent the sample pathway through the sample loops for FID and TCD.

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 1. Diagram of the simultaneous GC for gas product analysis. Configuration for gas sampling, where all valves are in the off position. Green lines represent the sample pathway through the sample loops for FID and TCD.

2.2.3. Simultaneous gas chromatography-mass spectrometry and flame ionization detector

A PerkinElmer 690 GC, equipped with a flame ionization detector and an autosampler, was paired with a PerkinElmer Clarus SQ 8T EI/CI MS operated in electron ionization (EI) mode for method development and validation. This setup aimed for simultaneous detection at FID and MS, enabling detailed hydrocarbon analysis and separation of fatty acids, with quantification on the FID and identification on MS. Thus, the method is referred to as simultaneous GC-FID/MS. A schematic diagram of the system is shown in Fig. 2.

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 2. Diagram of the simultaneous GC for liquid product analysis

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 2. Diagram of the simultaneous GC for liquid product analysis

3. Results and discussion

3.1. Gas analysis

3.1.1. Overall performance

Calibration curves were developed following the procedure detailed in Section 2.2.2. The slope, correlation coefficient, limit of detection (LOD), and limit of quantification (LOQ) are tabulated in Table S2. LOD and LOQ were calculated using Eqs. (2) and (3), respectively at atmospheric pressure. Correlation coefficients >0.99 were considered satisfactory. Fig. 3 represents the chromatographic profile of the gas standard mixture under the chromatographic conditions described in Section 2.1.1. Both chromatograms displayed well-distinguishable peaks of hydrocarbons and inorganic gases. Silva, et al. [42] has used a single column system, with TCD and FID in series, achieving similar separation, however with a longer run time, for 33.3 min. Moreover, most of the developed methods have been using a methanizer in conjunction of FID, to quantify fixed gases such as carbon monoxide and dioxide, adding one more step before the detector, while the present method avoids any kind of chemical conversion to detect such gases [43].

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 3. GC-FID/TCD chromatograms of gas standard mixture containing inorganic gases and light hydrocarbons.

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 3. GC-FID/TCD chromatograms of gas standard mixture containing inorganic gases and light hydrocarbons.

3.2. Liquid analysis

3.2.1. Overall performance

Fig. 4 presents the chromatograms of an in-house liquid mixture comprising C5-C17 alkanes and fatty acids (C3:0, C4:0, C6:0, C8:0, C9:0, C10:0, C12:0, C14:0, C16:0, C18:0, and C18:1). These compounds were identified using the National Institute of Standards and Technology (NIST) Library (2017), where the software matches an analyte's mass spectrum with those available in the database, and a match factor of 700 or above is considered a fair match [44]. Visual confirmation was additionally performed for the major ions present. Notably, most hydrocarbons were eluted before fatty acids due to the high polarity of the column. Particularly, C18:0 and C18:1 were well resolved.

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 4. GC–MS/FID chromatograms of alkanes and fatty acids mixture without derivatization.

Journal of Chromatography A, Volume 1741, 2025, 465641: Fig. 4. GC–MS/FID chromatograms of alkanes and fatty acids mixture without derivatization.

4. Conclusion

The in-house developed GC methods for analyzing gas and liquid pyrolytic products underwent rigorous validation through various approaches. For gas analysis, validation included calculations of both volume and mass concentrations, while liquid analysis was validated through three separate analyses employing different instruments. These methods enabled single-run identification and quantification of light hydrocarbons, fixed gases, a broad range of liquid hydrocarbons, and fatty acids without derivatization. In particular, the liquid product analysis quantified all GC-elutable compounds, allowing for accurate characterization of complex pyrolysis mixtures, which is different from most studies that applied area normalization for quantification.

These validated analytical methods have extended applications in characterizing general pyrolysis products comprising highly complex mixtures of hydrocarbons and oxygenates. They are useful for pyrolysis studies such as evaluating reaction parameters, learning reaction mechanisms, and assessing catalyst selectivity. The combination of simplicity, accuracy, and time saving features position these methods as indispensable tools for analyzing intricate mixtures.