Solvent-assisted stir bar sorptive extraction and gas chromatography–mass spectrometry with simultaneous olfactometry for the characterization of aroma compounds in Japanese Yamahai-brewed sake

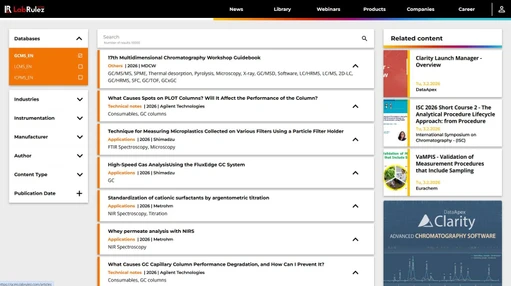

- Photo: Food Chemistry, Volume 405, Part A, 2023, 134640: Fig. 3. OPLS-DA of the aroma compounds: (A) score plot and (B) loading plot. Yamahai-brewed and Sokujo-brewed sake are represented by black and open symbols, respectively. R2X (cum): 0.844, R2Y (cum): 0.96, Q2 (cum): 0.919. Compounds that are classified as log Kow < 2, log Kow > 2, and unknown are represented by black squares, open circles and gray diamonds, respectively. Aroma compound numbers listed in Table 1 are indicated alongside the symbols. Aroma compounds of FD factor = 4096 and FD factor between 256 and 1024 are highlighted in bold underlined and underlined numbers, respectively. (1) ethyl propanoate, (2) ethyl butyrate,(3) ethyl isovalerate, (4) isobutanol, (5) isoamyl acetate, (6) 4-methyl-3-penten-2-one, (8) ethyl hexanoate, (9) dimethyltrisulfide, (10) unknown-1, (11) acetic acid, (12) methional, (13) unknown-2, (14) unknown 3, (15) benzaldehyde,(16) Ethyl 2-hydroxy-4-methylvalerate, (17) isobutyric acid, (18) butanoic acid, (19) 2-phenylethanal, (20) isovaleric acid, (21) diethyl succinate, (22) methionol, (23) ethyl phenylacetate, (24) phenethyl acetate, (25) hexanoic acid, (26) guaiacol, (28) 2-phenyl-2-butenal, (29) 5-octanolide, (30) 4-methyl-5,6-dihydropyran-2-one, (31) 4-nonanolide, (32) HEMF isomer (RI 2078), (33) unknown-4, (34) HEMF isomer (RI 2101), (35) unknown 5, (36) diethyl 2-hydroxypentanedioate, (37) 4-vinylguaiacol, (38) Ethyl mandelate, (39) 4-ethoxycarbonyl-γ-butanolactone, (40) 3-hydroxy-4-phenyl-2-butanone, (41) ethyl 2-hydroxy-3-phenylpropanoate, (42) isoeugenol, (43) g-6-(Z)-dodecenolactone, (44) vanillin, (45) unknown-6.

In the study published in the Food Chemistry journal, researchers from the Industrial Research Institute of Ishikawa, Japan, and GERSTEL K.K., Tokyo, Japan investigated the aroma compounds of Yamahai-brewed sake, a Japanese rice-based alcoholic beverage produced through natural lactic acid fermentation, known for its complex flavor compared to Sokujo-brewed sake made with pure lactic acid.

Using solvent-assisted stir bar sorptive extraction (SA-SBSE) combined with gas chromatography–olfactometry/mass spectrometry (GC-O/MS), the researchers confirmed that SA-SBSE enhances sensitivity and increases the number of detected odor-active compounds compared to SBSE alone. The analysis revealed that Yamahai-brewed sake, especially with a low rice polishing ratio, contains higher levels of polar aroma compounds. Quantification of 11 characteristic aroma compounds showed that compounds like ethyl mandelate, ethyl 2-hydroxy-4-methylvalerate, and the newly identified γ-6-(Z)-dodecenolactone were more abundant in Yamahai-brewed sake. These findings enhance the understanding of Yamahai-brewed sake's unique flavor profile and the effectiveness of SA-SBSE in aroma compound analysis.

The original article

Solvent-assisted stir bar sorptive extraction and gas chromatography–mass spectrometry with simultaneous olfactometry for the characterization of aroma compounds in Japanese Yamahai-brewed sake

Tetsuya Sasaki, Nobuo Ochiai, Yuya Yamazaki, Kikuo Sasamoto

Food Chemistry, Volume 405, Part A, 2023, 134640

https://doi.org/10.1016/j.foodchem.2022.134640.

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

Highlights

- Aroma compounds of Yamahai-brewed sake, made by natural lactic acid fermentation, were analyzed.

- A combination of SA-SBSE and GC-O/MS is effective to analyze polar aroma compounds in sake.

- Polar compounds were more abundant in Yamahai-brewed sake than in Sokujo-brewed sake.

- γ-6-(Z)-dodecenolactone, newly identified in sake, was more abundant in Yamahai-brewed sake.

Abstract

Yamahai-brewed sake, a Japanese alcoholic beverage brewed from rice and produced via natural lactic acid fermentation, has a complex and rich flavor compared with Sokujo-brewed sake, brewed with a general method using pure lactic acid. This study aimed to characterize the aroma compounds in Yamahai-brewed sake using solvent-assisted stir bar sorptive extraction (SA-SBSE) with gas chromatography–olfactometry/mass spectrometry (GC-O/MS) and to confirm the enhanced sensitivity of GC-O/MS with SA-SBSE compared with SBSE alone. SA-SBSE with GC-O/MS increased the number of detected odor-active compounds and improved the FD factor sensitivity of Yamahai-brewed sake. SA-SBSE-GC–MS analysis of three pairs of Yamahai-brewed and Sokujo-brewed sake showed higher polar aroma compound content in Yamahai-brewed sake with a low rice polishing ratio. Quantification of 11 characteristic aroma compounds with a wide range of log Kow values revealed that several compounds, including ethyl mandelate, ethyl 2-hydroxy-4-methylvalerate, and the newly identified γ-6-(Z)-dodecenolactone, were more abundant in Yamahai-brewed sake.

2. Materials and methods

2.1. Samples

Six sake samples were provided by Shata Shuzo Co., ltd (Ishikawa, Japan). Three samples (Y60, Y45, and Y35) were brewed using the Yamahai brewing method, and three (S60, S45, and S35) were brewed using the Sokujo brewing method.

Y60 and S60 were made from the same rice with a polishing ratio, called Seimai-buai, of 60 %. Rice polishing is the process by which the outer layer is polished using the rice polishing machine. The outer layers of unpolished rice contain large amounts of fats, minerals and proteins that spoil the flavor of sake. Highly polished rice is used to brew premium type of sake that has fruity aroma, such as apple and banana, derived from ethylcaproate and isoamyl acetate (Ohashi, K., 2007). The polishing ratio represents the weight of the polished grain as a percentage of the original unpolished grain weight. In the case of Y60 and S60, the outer 40 % of the grain is removed, leaving the central 60 %. A low polishing ratio means that the rice is highly polished. Y45 and S45 were produced from the same rice with a polishing ratio of 45 %. Similarly, Y35 and S35 were made from the same rice with a polishing ratio of 35 %. All samples were manufactured as commercial products.

2.2. Chemicals

Acetone, dichloromethane, diisopropyl ether, and sodium chloride (NaCl) were purchased from FUJIFILM Wako Pure Chemical Corporation (Osaka, Japan). Acetone and dichloromethane were of the grade used for pesticide residue and polychlorinated biphenyl tests. Diisopropyl ether and NaCl were of special reagent grade. The standard alkane mixture (C9-C40) was purchased from GL Science Inc. (Tokyo, Japan). Ethyl propanoate, ethyl butyrate, ethyl isovalerate, isobutanol, isoamyl acetate, 4-methyl-3-penten-2-one, isoamyl alcohol, ethyl hexanoate, dimethyltrisulfide, methional, benzaldehyde, ethyl 2-hydroxy-4-methylvalerate, diethyl succinate, methionol, ethyl phenylacetate, phenethyl acetate, guaiacol, phenethyl alcohol, 5-octanolide, 4-nonanolide, 2-ethyl-4-hydroxy-5-methyl-3(2H)-furanone (HEMF), 4-vinylguaiacol, ethyl mandelate, isoeugenol and vanillin (no. 1–9, 12, 15, 16, 21–24, 26, 27, 29, 31, 32, 34, 37, 38, 42, and 44 in Table 1) were purchased from Tokyo Chemical Industry Co., ltd. Acetic acid, isobutyric acid, butyric acid, isovaleric acid, hexanoic acid (no. 11, 17, 18, 20, 25), and sotolone were purchased from FUJIFILM Wako Pure Chemical Corporation. 2-Phenylethanal (no. 19) was purchased from Merck Corporation (Darmstadt, Germany). 2-Phenyl-2-butenal (no. 28) was purchased from Alfa Aesar (Ward Hill, MA, USA). 4-Methyl-5,6-dihydropyran-2-one (no. 30) was purchased from Angene International ltd. (Nanjing, China). Diethyl 2-hydroxypentanedioate and ethyl 2-hydroxy-3-phenylpropanoate (no. 36 and 41) were purchased from Toronto Research Chemicals (Toronto, ON, Canada). 4-Ethoxycarbonyl-γ-butanolactone (no. 39) was purchased from UkrOrgSyntez ltd. (Kyiv, Ukraine). γ-6-(Z)-dodecenolactone (no. 43) was procured from Soda Aromatic Co., ltd. (Tokyo, Japan). The purities of diethyl 2-hydroxypentanedioate and 4-ethoxycarbonyl-γ-butanolactone were over 90 % and 85 % respectively. The purities of other aroma compounds were over 95 %.

2.3. Aroma compound extraction using SA-SBSE and SBSE

Aroma compounds in the sake samples were extracted using SA-SBSE (Ochiai, Sasamoto, David, & Sandra, 2016). Stir bars (Flex Twister) coated with 63 μL of PDMS (10 mm length × 1.0 mm thickness) were obtained from GERSTEL GmbH & Co. KG (Mülheim an der Ruhr, Germany). For the solvent-swollen PDMS stir bar in SA-SBSE, 105 μL of the mixture with diisopropyl ether and dichloromethane (1:1) were added to a PDMS stir bar in a 2-mL glass vial, and the PDMS stir bar was then laid down and left for 30 min in the sealed vial before extraction. Sake samples were twofold diluted with ultrapure water before extraction. Subsequently, 5 μL of the twofold diluted sample were transferred into a 10-mL glass vial, and 30 % NaCl was added to the sample and dissolved. The (solvent-swollen) PDMS stir bar was added to the sample vial and extracted for 1 h at room temperature (approximately 25 °C) with a constant stirring rate of 800 rpm. The stir bar was then removed from the sake sample and dried on a filter paper. Next, the PDMS stir bar was added to 500 μL of acetone in a 10-mL glass vial and stirred for 30 min at a constant stirring rate of 350 rpm for aroma compound back extraction into acetone. SBSE was performed using the same method but without the solvent swelling process of the PDMS stir bar.

2.4. Large volume injection using a thermal desorption unit

Large volume injection (LVI) of the acetone extract (obtained from solvent back extraction) was performed using a thermal desorption unit (TDU, GERSTEL) connected to the cold injection system (CIS4, GERSTEL) inlet of an Agilent 7890A GC system (Agilent Technologies Inc., Palo Alto, CA, USA) equipped with an Agilent 5975C MS. After speed-controlled injection (at 0.85 μL/s) into a glass microvial in the TDU liner at 30 °C, the TDU was programmed from 30 °C (held for 0.5 min) at 140 °C/min to 80 °C (held for 7 min) with a 100 mL/min desorption flow. Desorbed compounds were focused on a Tenax TA packed liner in the CIS4 at 20 °C using liquid N2. After desorption, the CIS4 was programmed from 20 °C to 240 °C (held for the total GC run time) to inject the trapped compounds into the analytical column. The injection was performed in splitless mode.

2.5. GC–O/MS analysis and AEDA

For the GC–O/MS analyses, 50, 200, or 800 μL LVI of the original acetone extract, i.e., nondiluted extract, was performed. The acetone extract was diluted to 1:4, 1:16, 1:64, and 1:256 with acetone, and 50 μL LVI of the diluted acetone extract was performed for the diluted extracts. Because the size of the microsyringe was 250 μL, the 800 μL LVI of the acetone extract was performed by repeating the 200 μL LVI four times while maintaining the CIS4 at 20 °C.

Separations were performed on a 60 m × 0.25 mm i.d. × 0.25 μm film thickness DB-HeavyWax column (Agilent). The column temperature was programmed from 40 °C (3-min hold) to 250 °C (15-min hold) at a rate of 5 °C/min. Helium was used as carrier gas at a flow rate of 1.2 mL/min. After 60 min of GC–O/MS analysis, the capillary column was back-flushed at a flow rate of 3.1 mL/min from the outlet to the inlet at 250 °C (10-min hold). The flow gas from the column exit was split to the MS and a sniffing port system (ODP3, GERSTEL) with a split ratio of 1:1. The MS was operated in scan mode using electron ionization at 70 eV. The scan range was set from m/z 33–300 and a sampling rate of three, thereby resulting in a scan rate of 2.72 scan/s. The aroma compounds were identified based on retention index (RI) and mass spectra. The RIs were compared with those of the authentic compounds and Aroma Office 2D database ver. 7 (Gerstel KK, Tokyo, Japan). Aroma Office 2D is the most comprehensive database for aroma compounds (>116,000 entries). This software has a function to search RIs of aroma compounds from many literature references. The mass spectra were compared with those of authentic compounds and the Wiley/NIST database.

The FD factor and odor quality were confirmed by two trained panelists. Each panelist sniffed every sample twice with GC–O. The two detections by both panelists were determined as odor detection of the aroma compounds in each sample. Odor detections in the 800, 200, and 50 μL analyses of the original acetone extracts and 50 μL of the diluted acetone extract (1:4, 1:16, 1:64, and 1:256) correspond to the FD factors of 1, 4, 16, 64, 256, 1024, and 4096, respectively. The FD factor of each compound signifies the maximum dilution ratio of the odor detection sample diluted from 800 μL of the original acetone extract. If no odor was detected in the 800 μL analysis of the original extract, the FD factor was 0.

2.6. GC–MS analysis

For the GC–MS analyses, we performed 200 μL LVI of the acetone extract. The separations were performed on a 30 m × 0.25 mm i.d. × 0.25 μm film thickness DB-Wax UI column (Agilent). The column temperature was programmed from 40 °C (3-min hold) to 240 °C (17-min hold) at a rate of 5 °C/min. Helium was used as carrier gas at a flow rate of 1.2 mL/min. After 60 min of the GC–MS analysis, the capillary column was back-flushed at a flow rate of 3.1 mL/min from the outlet to the inlet at 240 °C (10-min hold). The MS was operated in the simultaneous selected ion monitoring (SIM)/scan mode using electron ionization at 70 eV. The scan range was set from m/z 33–300 and a sampling rate of three, thus resulting in a scan rate of 2.72 scan/s. Each sample was analyzed in triplicates. The peak areas of the identified compounds in the GC–MS data were extracted using MassHunter Quantitative Analysis software ver. 10.0 (Agilent Technologies). The SIM data were used to extract the peaks of dimethyltrisulfide (no. 9), methional (no. 12), HEMF (no. 32 and 34), unknown 4 (no. 33), and γ-6-(Z)-dodecenolactone (no. 43). The scan data were used to extract the peaks of the other compounds. The monitoring ions of each compound are listed in Table 1.

2.7. Aroma compound quantification

For the quantification of the 11 aroma compounds (1, 8, 12, 15, 16, 28, 29, 30, 31, 38, and 43), a standard addition calibration was performed as described previously (Ochiai, Sasamoto, David, & Sandra, 2016). Several standard solutions containing different amounts of aroma compounds in ethanol were prepared. Subsequently, 8 μL of the standard solution and 5 μL of the two fold diluted sake sample were transferred into a 10-mL glass vial. NaCl (30 %) was added to the mixture, and dissolved. The amounts of the aroma compounds in the standard solutions were adjusted to spike the concentrations in the sake samples. The estimated concentrations in sake after spiking the aroma compounds are listed Table S1. Five points in standard addition calibration curves between 0 and 320 μg/L (compound 1), 0 and 800 μg/L (compounds 8 and 15), 0 and 32 μg/L (compound 12), 0 and 160 μg/L (compound 16), 0 and 8000 μg/L (compound 30), or 0 and 8 μg/L (compounds 28, 29, 31, 38, and 43) were used for the quantitation. The solvent swollen PDMS stir bar was added to the sample vial, and SA-SBSE was performed as mentioned above. Acetone extracts were obtained with the back extraction of SA-SBSE, and 100 μL LVI of the acetone extract was performed. The separation conditions were the same as those for GC–MS analysis using a 30 m × 0.25 mm i.d. × 0.25 μm film thickness DB-Wax UI column (Agilent). The monitoring ions, listed in Table 1, were extracted using MassHunter Quantitative Analysis software ver. 10.0 (Agilent Technologies). The peak areas of compounds 12 and 43 were obtained from the SIM data. The peak areas of other compounds were extracted from the scan data. Calibration curves with a determination coefficient > 0.99 were created using the peak areas. The concentrations of aroma compounds in sake were calculated using the intersection of the calibration curve and the GC–MS peak intensity axis.

2.8. Orthogonal partial least squares discriminant analysis

Orthogonal partial least squares discriminant analysis (OPLS-DA) was performed using SIMCA v.14.0 (Umetrics, Umeå, Sweden) after the data were mean-centered and unit variant-scaled.

4. Conclusions

We applied SA-SBSE–GC–O/MS to AEDA for the first time to determine the sensitivity and coverage improvement of the polar compounds in sake. Forty-five odor-active compounds were detected with SA-SBSE–GC–O/MS, which is 11 more than those detected with SBSE-GC–O/MS. We observed FD factor sensitivity improvement in the case of 24 compounds. SA-SBSE combined with GC–O/MS is an effective method for the accurate and comprehensive analysis of odor-active compounds in aroma science using GC analysis with green extraction technique, where highly efficient recovery of polar compounds is required.

The odor-active compounds detected with SA-SBSE–GC–O/MS were compared in Yamahai-brewed sake and Sokujo-brewed sake from the same brewery with SA-SBSE-GC–MS, and the aroma compound characteristics of Yamahai-brewed sake were investigated for the first time. OPLS-DA of 43 odor-active compounds and the quantitative analysis of 11 selected compounds aided in ascertaining that Yamahai-brewed sake contains several polar and apolar compounds such as ethyl mandelate, ethyl 2-hydroxy-4-methylvalerate, and γ-6-(Z)-dodecenolactone. In addition, quantitative analysis with SA-SBSE–GC–MS yielded concentration data for compounds with a wide polarity range (log Kow values of 0.41–3.33) and concentration range (few μg/L to 1400 μg/L). Thus, the application of SA-SBSE–GC–O/MS holds potential for the analysis of sake and other alcoholic beverages.

- Solvent-assisted stir bar sorptive extraction and gas chromatography–mass spectrometry with simultaneous olfactometry for the characterization of aroma compounds in Japanese Yamahai-brewed sake. Tetsuya Sasaki, Nobuo Ochiai, Yuya Yamazaki, Kikuo Sasamoto. Food Chemistry, Volume 405, Part A, 2023, 134640. https://doi.org/10.1016/j.foodchem.2022.134640.