Full Evaporative Vacuum Extraction─A Quantitative and Green Approach for Analysis of Semivolatile Organic Compounds in Drinking Water and Surface Water Using GC–MS

- Photo: Anal. Chem. 2023, 95 (8), 3959-3967: graphical abstract

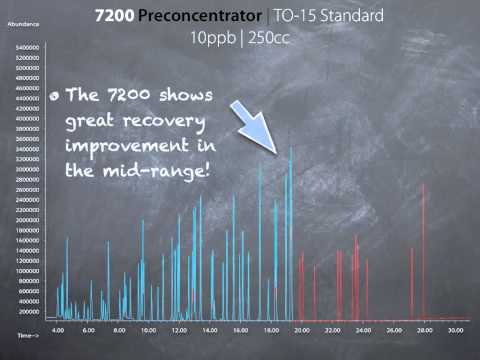

- Video: Entech Instruments: Entech Instruments 7200 Chromatography

In the research article recently published in ACS Analytical Chemistry journal the researchers Weier Hao and Daniel B. Cardin from Entech Instruments Inc., describe a Full Evaporative Vacuum Extraction (FEVE) method for efficient analysis of a wide range of semivolatile organic compounds (SVOCs) in water.

This study introduces a Full Evaporative Vacuum Extraction (FEVE) method for analyzing (semivolatile organic compounds SVOCs) in drinking and surface water using sorbent pens. The method involves a two-stage process to capture both lighter and heavier SVOCs, followed by desorption into a GC-MS with optimized parameters for enhanced sensitivity. The sorbent pens can be stored for up to 10 days with minimal loss in analyte recovery. Testing 10 water samples, the method detected 69 analytes, none of which exceeded California Proposition 65 safety limits.

The original article

Full Evaporative Vacuum Extraction─A Quantitative and Green Approach for Analysis of Semivolatile Organic Compounds in Drinking Water and Surface Water Using GC–MS

Weier Hao, Daniel B. Cardin

Analytical Chemistry 2023 95 (8), 2959-3967

DOI: 10.1021/acs.analchem.2c03414

licensed under CC-BY 4.0

Selected sections from the article follow.

Abstract

Full evaporative vacuum extraction (FEVE) was developed in this work for analysis of a broad range of semivolatile organic compounds (SVOCs) in drinking water and surface water. Sorbent pens are used in a two-stage process that first evaporates the sample matrix through sorbent beds under vacuum to recover the lighter SVOCs, followed by the application of a higher temperature and stronger vacuum to the sample vial to recover the remaining heavier SVOCs once the matrix has evaporated. After extraction, the sorbent pens are desorbed into a GC–MS using a uniquely designed “splitless” delivery system to maximize sensitivity. Critical extraction and desorption parameters that affect the method performance were optimized. After FEVE, the sorbent pens can be stored for 7–10 days at room temperature while maintaining a less than 15% loss in analyte recovery. As a proof of concept, 10 drinking water and surface water samples were analyzed using this method. 69 analytes were detected in these water samples, with the highest concentration of 1986 ng/L for bromacil. Heptachlor epoxide, chlorpyrifos, metolachlor, butachlor, and 2,3′,4′,5-tetrachlorobiphenyl were detected in four samples. None of the analytes were above the health and safety thresholds set by California Proposition 65.

Anal. Chem. 2023, 95 (8), 3959-3967: graphical abstract.

Anal. Chem. 2023, 95 (8), 3959-3967: graphical abstract.

Experimental Section

Design of FEVE

The FEVE sorbent pen (FSP) has a special design that extends into the neck of 2 mL FEVE sample vials to ensure recovery of heavy SVOCs. To capture a broad range of SVOCs, the sorbent bed consists of two sorbents in series: first, PDMS-coated glass beads and then 35/60 mesh Tenax TA. This FSP design is shown in Figure 1. PDMS-coated glass beads were chosen as a first bed to minimize the desorption heat needed to recover the heavier and the more thermally labile compounds, thereby optimizing their recoveries. For analysis of more volatile compounds, a stronger third sorbent like Carboxen or Carbosieve can be added in the FSP to capture these lighter compounds. However, for the suite of SVOCs in this study, a third sorbent was not necessary.

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 1. Photograph (a) and cross-section (b) of an FSP showing the internal sorbent beds: PDMS-coated glass beads (red) and Tenax (white). The FSPs are stored in a sleeve when not in use (c).

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 1. Photograph (a) and cross-section (b) of an FSP showing the internal sorbent beds: PDMS-coated glass beads (red) and Tenax (white). The FSPs are stored in a sleeve when not in use (c).

As shown in Figure 2, a 2 mL sample vial with 1 mL of the water sample was attached to an FEVE vacuum sleeve, and then, an FSP was inserted. A silicone O-ring was placed between the top of the sample vial and the bottom of the vacuum sleeve to create a leak-tight seal. The FEVE assemblies were placed into the extraction module shown in Figure 3. A top plate was used to compress the two upper vacuum sleeve O-rings against the vacuum manifold to ensure a leak-tight seal. The multi-position design of the manifold allows for up to 30 samples to be extracted simultaneously.

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 2. Components comprising the FEVE sample assembly, including 2 mL sample vial with 1 mL of the water sample (a), FEVE vacuum sleeve with a vial nut and silicone O-rings (b), and FSP (c). Photograph (d) and cross-section of the completed assembly showing the entrance of the FSP extending into the vial to ensure recovery of heavy SVOCs (e).

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 2. Components comprising the FEVE sample assembly, including 2 mL sample vial with 1 mL of the water sample (a), FEVE vacuum sleeve with a vial nut and silicone O-rings (b), and FSP (c). Photograph (d) and cross-section of the completed assembly showing the entrance of the FSP extending into the vial to ensure recovery of heavy SVOCs (e).

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 3. Front cross-section view of the FEVE module during extraction of multiple water samples (a). Top-down view of the FEVE top plate, FSP cooling fan, vacuum output, and 30 FEVE sample assemblies in place (b).

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 3. Front cross-section view of the FEVE module during extraction of multiple water samples (a). Top-down view of the FEVE top plate, FSP cooling fan, vacuum output, and 30 FEVE sample assemblies in place (b).

The FEVE process consists of four major steps: vacuum verification, matrix evaporation, high-vacuum dehydration, and high-temperature diffusive desorption. During vacuum verification, the FEVE instrument is pumped down through the low-vac valve to reach a target vacuum pressure. Then, the valve is turned off, and the rate of pressure increase is used to determine whether the system is leak-tight. After the vacuum verification standard is met, the matrix evaporation starts. The low-vac valve is left on to help slowly remove the water matrix under vacuum. When the pressure of the instrument drops below 10 Torr, the process advances to high-vacuum dehydration, where the high-vac valve is turned on to provide a stronger vacuum, pulling the remaining volatile matrix in the vial through the FSP sorbents to the pump. When the pressure drops to 1 Torr, the sample vials are heated at 200 °C for 7.5 min. This step helps transfer the heavier SVOCs from the vials to the sorbents. An FSP cooling fan is turned on at this stage to keep the FSP sorbent cool to maximize its adsorption capacity. After the vial heater is cooled down, the FSPs are ready for TD–GC–MS analysis. The entire FEVE process takes 4–6 h, depending on the number of samples extracted simultaneously. Extraction of 30 samples in 6 h equates to an average time of 12 min per sample. As this is approximately half the time of a standard GC cycle, one FEVE system can provide maximum throughput for two GC–MS systems.

TD and GC–MS

After completion of the FEVE extraction process, the FSPs were loaded into a 30-position sorbent pen sample tray. The sample handling was performed using an SPR40 sample preparation rail (Entech Instruments) with full automation. The 5800-SPDU Sorbent Pen Desorption Unit (Entech Instruments) was used as the TD system to deliver the analytes to the GC–MS. A 7890B/5977C GC–MS (Agilent Technologies, Santa Clara, CA) was used for optimization of the extraction and desorption parameters. A Trace 1310/ISQ 7000 GC–MS (Thermo Fisher Scientific, Waltham, MA) with an advanced electron impact ion source operating in the selected ion monitoring mode was utilized to further optimize the detection limits of the method, evaluate the method, and analyze the water samples. A UAC-1MS precolumn (5 m × 0.53 mm × 0.15 μm, methylpolysiloxane; Quadrex Corp, Bethany, CT) was used to collect the SVOCs during sample desorption while using a 7–8 mL/min flow rate, with excess flow eliminated through a split tee positioned at the junction between the precolumn and the analytical column. The analytical column used for GC separation was an Agilent HP-5MS (30 m × 0.25 mm × 0.5 μm, 5%-phenyl-methylpolysiloxane). The carrier gas was helium, at a flow rate of 1.2 mL/min.

Figure 4 shows the configuration of the 5800-SPDU, the precolumn (column 1), the analytical column (column 2), and the flow and split control. This design of the instrument enables sorbent pen pre-purging and pre-heating, desorption, GC delivery, split control, and residual backflushing during the analysis of each sample. After an FSP is inserted into the desorption unit, valves 2 and 4 are turned on during preheating, thereby bypassing the FSP. Once the desorption starts, valves 1 and 4 are turned on, enabling desorption flow through the FSP to deliver SVOCs to column 1. During desorption, compounds more volatile than the lightest analyte of interest are split out through valve 4. After desorption, valves 1 and 3 are tuned on, allowing the analytes to proceed splitlessly to column 2. By using a thicker film on column 2 than that on column 1, the analytes dynamically refocus on column 2, resulting in narrower chromatographic peaks. In practice, column 2 with a film thickness of 0.25 or 0.5 μm is recommended, while column 1 is 0.15 μm. The length of column 1 can be greater than 5 m if longer desorption time is needed. During transfer of the analytes in the two columns, the desorption unit is baked at 260 °C to eliminate potential carryover in the FSP. After the heaviest analyte of interest is eluted out from column 1 and starts separating on column 2, valves 2 and 3 are turned on to backflush unwanted heavy compounds out through the entrance of column 1. Finally, the desorption unit cools down and returns to the idle status where valves 2 and 4 are on and ready for the next sample. The valve controls and flow directions of each stage are shown in Figure S2 in the Supporting Information. The GC oven temperature was held at 40 °C for 3 min during sample desorption, ramped at 12 °C/min to 160 °C, then ramped at 8 °C/min to 320 °C, and held for 1 min until the end of the run. Data acquisition and analysis were performed using Agilent MassHunter Workstation, Thermo Chromeleon, Entech SPRINT software, and Microsoft Excel.

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 4. Configuration of the 5800-SPDU, two column design, and split control of the TD–GC–MS system. Column 1: Quadrex UAC-1MS (5 m × 0.53 mm × 0.15 μm). Column 2: Agilent HP-5MS (30 m × 0.25 mm × 0.5 μm).

Anal. Chem. 2023, 95 (8), 2959-3967: Figure 4. Configuration of the 5800-SPDU, two column design, and split control of the TD–GC–MS system. Column 1: Quadrex UAC-1MS (5 m × 0.53 mm × 0.15 μm). Column 2: Agilent HP-5MS (30 m × 0.25 mm × 0.5 μm).

Conclusions

In this work, FEVE, a quantitative and green approach, was designed, developed, evaluated, and applied to analysis of 123 SVOCs in drinking water and surface water samples. This method enables quantification of a broad range of semivolatile compounds simultaneously, meanwhile providing a high level of sensitivity, accuracy, and precision. The extraction and analysis process is highly automated, enabling a simple and efficient workflow for analytical laboratories, and completely eliminates the use of solvents during sampling, analysis, and cleanup. Besides drinking water and surface water, FEVE also has the potential to be applied to other matrices. For example, for analysis of more complex environmental, biological, and foodstuff samples, after a simple pre-extraction to remove suspendid solids in the samples, a mixture of water and extract can be analyzed using FEVE. A 6 mL version of the FEVE technology will also be available to analyze up to 5 mL of the sample, which can further lower the detection limits.

- Full Evaporative Vacuum Extraction─A Quantitative and Green Approach for Analysis of Semivolatile Organic Compounds in Drinking Water and Surface Water Using GC–MS Weier Hao, and Daniel B. Cardin. Anal. Chem. 2023, 95 (8), 3959-3967. DOI: 10.1021/acs.analchem.2c03414