News from LabRulezGCMS Library - Week 51, 2025

LabRulez: News from LabRulezGCMS Library - Week 51, 2025

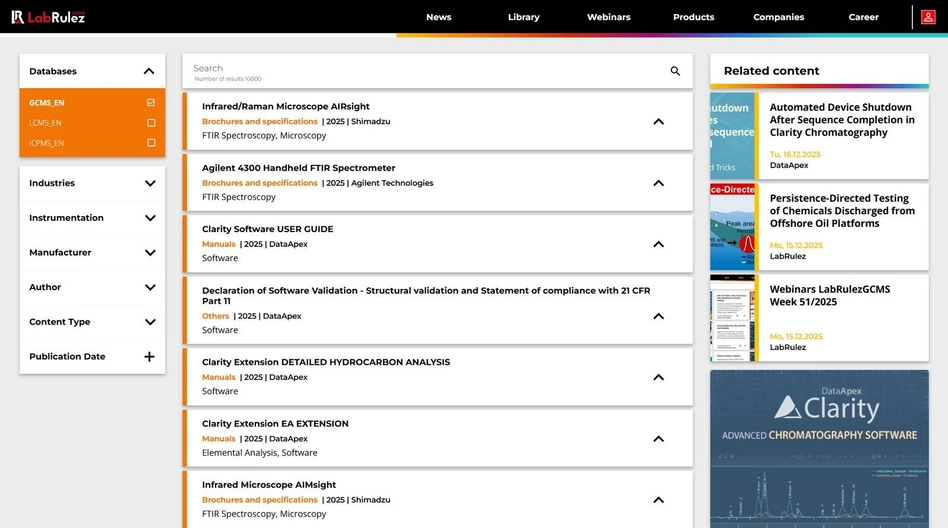

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 15th December 2025? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you application notes by Agilent Technologies, Shimadzu and brochure by Thermo Fisher Scientific!

1. Agilent Technologies: Increased Thermal Stability of the DB‑5Q GC Column

Increased signal-to-noise for trace level concentrations of controlled substances

- Application note

- Full PDF for download

The analysis of controlled substances by gas chromatography/mass spectrometry (GC/MS) requires a high level of confidence and thus requires a method that provides optimal data quality. Identification of controlled substances relies heavily on comparison of mass spectra to commercially available spectral libraries, and increased column bleed can cause spectral interference at high temperatures. These interferences can lead to poor library matching probabilities.1-3 The Agilent J&W 5Q series of gas chromatography columns provide the most thermally stable columns available, which helps to decrease spectral interference due to column bleed and improves data accuracy.

Poor thermal stability will cause an increase in the slope of the baseline as the oven temperature is increased, leading to difficult peak integrations and inaccurate quantitation. Additionally, sloped or elevated baselines can lead to a decreased response and a loss of sensitivity for analytes eluting during the oven ramp or at the method’s upper temperature limits. Several commercially available 5ms type columns were compared to the Agilent J&W DB-5Q GC column to examine the impact thermal stability has on response at upper temperature limits.

Experimental

An Agilent 8890 GC system coupled with an Agilent 5977B mass selective detector (GC/MSD) with an inert extractor ion source was used for acquisition of data and MassHunter 10.0 Quantitative and Qualitative Analysis software was used for data analysis.

A representative toxicology mixture, the Agilent GC/MS forensic toxicology checkout mixture (part number 5190-0471) was used to monitor analytical performance. Calibration standards were prepared in methanol (MeOH) at concentrations ranging from 0.1 to 3.0 μg/mL. An internal standard mix was prepared at 10 μg/mL from individual stocks of methamphetamine-d3, diazepam-d5, and hydrocodone-d6 all purchased from Millipore Sigma (St. Louis, MO).

Results and discussion

The testing evaluated the Agilent J&W DB-5Q GC column for the analysis of controlled substances by GC/MS. The increased thermal stability of the DB-5Q is seen in the decreased baseline at higher temperatures, as seen in Figure 1, and also provides a decrease in the slope during the oven ramping program.

An increase in the slope of the baseline will also decrease the signal-to-noise ratio (S/N) of an analyte but will also make integration more difficult and lead to less accurate quantitative results. Figure 2 demonstrates the comparison of the DB-5Q and the commercially available 5ms type G column, and the impact to chromatography during the oven ramp. The S/N for the analytes on the oven ramp slope are a factor of ten or greater for the DB-5Q in comparison to the 5ms type G column.

Conclusion

The increased thermal stability of the Agilent J&W DB-5Q GC column demonstrated in this application note provides a decreased baseline at higher temperatures, which allows for an increased response for later eluting compounds at trace level concentrations. The baseline of the DB-5Q remains more consistent as the temperature is increased. This consistency allows for more accurate integration and quantitation for analytes eluting during oven ramping, in comparison to other commercially available 5ms-type columns. The robust DB-5Q column phase maintained peak shape for trace level basic compounds even when stressed with a heavy matrix and is an excellent choice for the analysis of controlled substance analysis.

2. Shimadzu: Quantitative Analysis of Anti-Degradant Additive (6PPD) in Tire Rubber Using Pyrolysis-GC-MS

- Application note

- Full PDF for download

User Benefits

- The simple analysis procedure required just cutting off a sample fragment and placing it in a sample cup without pretreatment.

- Utilizing a calibration standard that includes a resin solution allows for analysis under conditions that closely resemble those of samples, which improves the reliability of quantitative measurements.

- With Shimadzu’s Polymer Additive Library, it is possible to acquire information on the additives of identified compounds.

6PPD (N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine) is an anti-degradant (anti-oxidant) additive that is used in many rubber products. Its chemical structure is shown in Fig. 1. It plays an important role in tires by preventing degradation and extending its lifespan. However, when 6PPD reacts with ozone in the atmosphere, it forms a highly toxic substance called 6PPD-quinone (6PPD-Q).

As an automotive tire wears, microscopic particles are released from the tire into the environment. These particles, tire road wear particles (TRWP), contain 6PPD-Q along with many other chemical substances. On rainy days, these particles are washed into rivers and other bodies of water, where they accumulate in the environment as microplastics.

There are serious concerns about the negative effects these microplastics have on ecosystems and the environment. 6PPDQ has been shown to induce acute mortality in Salmonidae fish, specifically coho salmon. 1)

Currently, there is no commercial alternative that can maintain tire stability and performance with minimal impact on the environment. Research into alternatives requires accurately assessing 6PPD levels in rubber products and objectively determining whether alternative compounds offer equivalent stability and performance while having a reduced impact on the environment.

This article describes using a pyrolysis gas chromatograph mass spectrometer (Py-GC-MS) system to measure 6PPD levels in tire rubber.

Analysis Process

ISO/TS 21396describes a method for determining the mass concentration of TRWP in soil and sediment that uses Py-GC-MS. Similar to this method, Py-GC-MS was used for the analysis; however, this article employs optimized analytical conditions. A schematic diagram of the analysis processisshown in Fig. 2. For more information on the analysis conditions and results from the evolved gas analysis (EGA-MS, EGA/PY-3030D Multi-Shot Pyrolyzer AS-1020E Auto-Shot Sampler, Frontier Laboratories Ltd.) method described in Fig. 2, please see Application News No. 01-00901. The analysis conditions for the thermal desorption (TD)-GC/MS (GCMS-QP2020 NX) method used in this article are shown in Table 1. The thermal desorption temperature was chosen based on results obtained by the EGA-MS method.

Qualitative Analysis of Additive

The total ion current (TIC) chromatogram obtained from analyzing the tire rubber is shown in Fig. 4. A spectral library search was also performed using NIST-23 and Shimadzu’s Polymer Additives Library. The library search results for the peak that eluted at around 10.43 minutes are shown in Fig. 5. Based on the results from Shimadzu’s Polymer Additives Library, the peak was estimated to be the anti-degradant Nocrac 6C (a trade name for the chemical 6PPD).

Conclusion

This article presents an analysis of the additive 6PPD in tire rubber utilizing Py-GC-MS. Good results were obtained for calibration curve linearity, calibration standard repeatability, limit of quantification, and limit of detection. Shimadzu’s Polymer Additives Library was used to identify the additive.

3. Thermo Fisher Scientific: Gas chromatography analyzers for the oil & gas industry: upstream to downstream

- Brochure

- Full PDF for download

Gas chromatography (GC) plays a central role in the oil and gas industry, providing high-accuracy, high-speed analysis of complex hydrocarbon mixtures from upstream exploration through midstream transport to downstream refining and distribution. Across this value chain, GC supports regulatory compliance, product quality control, custody transfer, and process optimization. As the industry adapts to decarbonization goals and stricter environmental regulations, robust and automated analytical solutions have become essential for monitoring hydrocarbons, impurities, and trace components under demanding 24/7 operational conditions.

Thermo Scientific™ GC analyzers are engineered to meet these challenges, with the TRACE™ 1610 GC platform forming the backbone of a comprehensive portfolio of preconfigured and customizable systems. Its modular “Instant Connect” design enables rapid configuration of injectors, detectors, and valves, reducing downtime and simplifying maintenance. The platform supports multi-detector configurations—including FID, TCD, FPD, PDD, MS, and VUV—allowing a single analyzer to address a broad range of applications, from natural gas composition and BTU determination to sulfur species, fixed gases, and detailed hydrocarbon analysis .

Dedicated GC analyzer configurations are available for specific industry needs, including natural gas and natural gas liquids (NGA/NGL), refinery gas analysis (RGA), light hydrocarbons (LPG), oxygenates, aromatics (BTEX), permanent gases, and high-purity gas streams. Advanced techniques such as GC-VUV further simplify complex analyses like PIONA group-type characterization of gasoline, delivering comprehensive compositional data in a single run while reducing calibration effort and cost per sample. These systems are designed to comply with major ASTM, ISO, GPA, DIN, EN, and UOP standards, ensuring global regulatory alignment .

Complementing the hardware, Thermo Scientific™ Chromeleon™ Chromatography Data System (CDS) provides an integrated informatics backbone for method control, data processing, reporting, and connectivity to LIMS platforms. This unified approach enhances data integrity, improves workflow efficiency, and enables real-time decision-making across refinery and gas processing operations. Together, Thermo Scientific GC analyzers and integrated software solutions deliver reliable, scalable, and future-ready analytics for the evolving oil and gas industry.