News from LabRulezGCMS Library - Week 38, 2025

LabRulez: News from LabRulezGCMS Library - Week 38, 2025

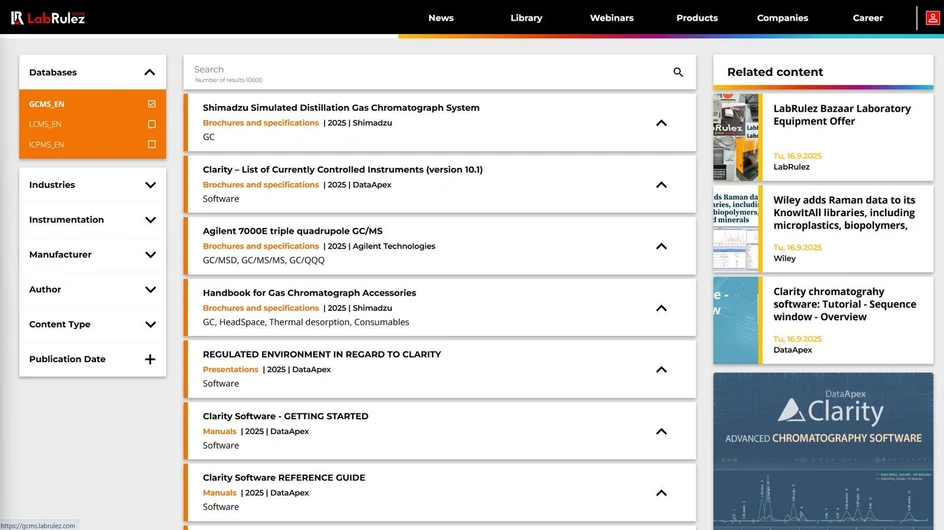

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 15th September 2025? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you posters by Agilent Technologies / ASMS, Shimadzu / ASMS and application note by EST Analytical!

1. Agilent Technologies / ASMS: Beyond Aligners: Unmasking Hidden Extractables and Leachables in Orthodontic Devices

- Poster

- Full PDF for download

Increasingly popular in orthodontics, clear aligners promised to users’ improved comfort, compliance and flexibility. It also came with prolonged intraoral exposure. The literature on the potential for leaching components of the polymer used to manufacture the invisible aligners is sparse. Despite the benefits, user submitted cases in the FDA retrospective analysis report several adverse effect ranging from swelling, hives, itchiness and even difficulty breathing1 . Previous works examined the potential of leaching in retainers but used conditions far from the in-vivo setting2 . We used samples closest to user conditions and harnessed the power of Gas Chromatography High Resolution Mass Spectrometry (GC-HRMS) and the power of curated and annotated libraries to find candidate compounds that could be at the origin of the reported adverse effects. We also used multivariate statistics to establish relationships between the compounds and metadata.

Experimental

Sample Analysis

Samples were analyzed using the Agilent 7250 accurate mass GC-qTOF equipped with the 8890 GC and a DB-5MS UI column (30m x 0.25 x 0.25). The inlet temperature was 280°C and the transfer line temperature was 325°C. The oven program was as follows: 50°C for 1 min, ramp at 25°C to 170°C, hold for 1 min; then ramp at 15°C to 300°C, hold for 10 min; then ramp at 20 °C to 325°C and hold for 5 min. The solvent delay was 4 min. The data were acquired in electron ionization (EI) mode using mass range 45 to 1000 m/z. The source temperature was 230°C, and the emission current was 5 µA. A mix of alkanes was run along with the samples and blanks and an Extractables and Leachables (E&L) standard mixture was run as a quality check.

Data Analysis

Retention indices were used in consolidating library matches in both the Agilent HRMS E&L library and the NIST23 library. Data analysis was conducted on Unknown Analysis software from Agilent that performs compound annotation based on library matching and retention index. All compounds were individually reviewed based on ExactMass, retention index delta and library match factor (Figure 2). Canonical Correlation Analysis was performed using the FactoMineR package in R.

Conclusions

The aligners used in the current study were approved in the late 90s when E&Ls methods were not as prominent or sensitive as they are today. This study stands out with:

- The first report of numerous E&L compounds with known potential adverse effects in a population of clear aligner users

- Providing an insight of the relationships between E&Ls and user’s metadata such as age, DWT and TSS

- Providing the necessary libraries to find parent compounds and their potential metabolites

2. EST Analytical: Optimization of 1,4-Dioxane and Ethanol Detection Using USEPA Method 8260

- Application note

- Full PDF for download

During the manufacture of pharmaceuticals, 1, 4-Dioxane is used as a cleansing agent. It is also a byproduct of plastic manufacturing. The most likely exposure to 1, 4-Dioxane is at an industrial site. However, if any 1, 4-Dioxane is released into the environment during manufacturing there is a potential for it to migrate into ground water. The fact that 1, 4-Dioxane is so miscible in water makes degradation of the chemical challenging. Ethanol, on the other hand, has been a popular gasoline additive. Since it burns more quickly and completely than gasoline, emissions from car exhaust are decreased. The downside of this is underground storage tank leakage and fuel spills cause ground water and drinking water to be contaminated with both the fuel and the ethanol additive. Since ethanol is also very miscible in water, the detection of ethanol contamination in water can be difficult.

There have been several innovations that help overcome the obstacles of detecting 1, 4-Dioxane and Ethanol. The first one is the SIM mode of the mass spectrometer. This mode allows better detection of hard to extract compounds. Furthermore, mass spectrometers are now equipped to run SIM/Scan, this not only helps detect more difficult compounds, but also enables the detection of an extensive list of USEPA Method 8260 compounds without having to run the samples twice. Advancements in purge and trap sampling have also facilitated better detection of these compounds. Most effective in this has been the ability to heat the samples. However, there are drawbacks to better detection. The most problematic of these is the tendency of 1, 4-Dioxane and Ethanol to “stick” to the glass ware. This susceptibility has caused many headaches in environmental labs.

This application note will investigate seven variations of purge and trap sampling. The data will then be evaluated in order to recommend the optimum purge and trap sampling parameters for your lab.

Experimental

The sampling system used for this study was the EST Analytical Evolution concentrator affixed with a Vocarb 3000 trap. The Centurion WS autosampler equipped with the syringe option was employed as the autosampler. The separation and analysis were performed by an Agilent 7890A Gas Chromatograph (GC) and 5975C inert XL Mass Spectrometer (MS). The GC was configured with a Restek Rxi-624 Sil MS 30m x 0.25mm x 1.4µm column. The purge and trap parameters used for this study are listed in Tables 1 and 2 while Table 3 shows the GC/MS parameters.

Conclusions

All seven purge and trap parameter iterations passed the USEPA Method 8260 requirements for linearity and method detection limits. The problem with some of the experimental parameters was found in the carryover and precision and accuracy studies. The carryover using the traditional sparge vessel showed a large amount of carryover for the Ethanol and 1, 4-Dioxane. Since the carryover was so high, the precision and accuracy data suffered. The Fritless/Bulbless sparge vessel, on the other hand, displayed much lower carryover for the Ethanol and 1, 4-Dioxane especially when the patented sparge bake was not used. However, the 1, 2, 4-Trichlorobenzene, Naphthalene and 1, 2, 3-Trichlorobenzene carryover after the 50ppb standard was above the lower limit of the curve. Thus, the sparge bake would be recommended in order to limit the carryover of the heavier compounds. The optimum purge and trap parameters proved to be the patented water extraction technique. This technique provided linearity and method detection limits that met the USEPA Method 8260 requirements, while providing excellent precision and accuracy data. During water extraction, the sample is transferred to an empty 40ml vial and then purged in the soil station of the Centurion. The “fresh” vial provides a clean sparge vessel for every sample thus limiting carryover for both the Ethanol and 1, 4-Dioxane and for the heavy compounds. This lack of carryover aided in providing optimum precision and accuracy and carryover results and would be the recommended method for examining these troublesome compounds.

3. Shimadzu / ASMS: Quantitation of Acetaldehyde, Ethylene Oxide, 2-Chloroethanol, Ethylene Glycol, 1,4-Dioxane & Diethylene Glycol in PEG 3350 by using dynamic headspace GC-MS/MS

- Poster

- Full PDF for download

Polyethylene glycol 3350 (PEG 3350) is used to treat occasional constipation and it is in a class of medications called osmotic laxatives. PEG 3350 is an addition polymer of ethylene oxide and water with formula H(OCH2CH2)n OH, in which n represents the average number of oxyethylene groups. The average molecular weight of PEG 3350 is 3015–3685 g/mol (Da). Acetaldehyde, Ethylene Oxide (EtO), 2-Chloroethanol (2-CE), Ethylene Glycol (EG), 1,4- Dioxane and Diethylene Glycol (DEG) are the probable impurities of PEG 3350. All these above impurities are highly toxic & hazardous substances.

As per the USP monograph, different chromatography techniques and sample preparation methods are used to quantify above mentioned impurities. This study reports a single sensitive and reliable analytical method for quantitation of all above impurities by using dynamic headspace (Trap) coupled with GC-MS/MS system. Limit of impurities and detail method of analysis are shown in table 1.

This study reports highly sensitive single method for the simultaneous quantification of multiple probable impurities of PEG 3350 by using dynamic headspace (Trap) coupled with triple quadrupole gas chromatography (GC-MS/MS) system.

Materials and methods

For this study, individual impurity reference standards were procured from Sigma Aldrich, whereas PEG 3350 powder sample was procured from local medical store. 10% of PEG 3350 powder sample solution (as such sample solution) and respective levels of matrixmatched calibration standard solutions were prepared in acetonitrile. Standard addition method was used to quantify impurities in the PEG 3350 sample. This method was part validated with respect to (w.r.t) precision, linearity/accuracy and sample analysis. GCMS-TQ8050 NX equipped with headspace sampler HS-20 NX (Trap) (Figure 1), manufactured by Shimadzu Corporation Japan, was used to quantify impurities in the PEG 3350 sample

Conclusion

- Trace level quantification of Acetaldehyde, EtO, 2-CE, 1,4-Dioxane, EG and DEG in PEG 3350 sample was successfully performed by using Shimadzu GCMS-TQ8050 NX with HS-20 NX (Trap) dynamic headspace sampler.

- Dynamic headspace mode outperforms the current regulatory limits, delivering multifold times more sensitivity compared to other injection techniques.

- Shimadzu GCMS-TQ8050 NX features a new highly efficient detector and superior noise reduction technology that enhance sensitivity and enables quantitation of impurities even at trace levels.