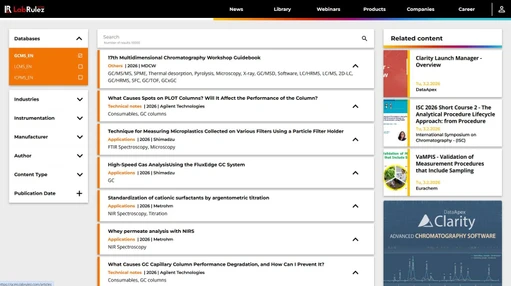

News from LabRulezGCMS Library - Week 02, 2026

LabRulez: News from LabRulezGCMS Library - Week 02, 2026

Our Library never stops expanding. What are the most recent contributions to LabRulezGCMS Library in the week of 5th January 2026? Check out new documents from the field of the gas phase, especially GC and GC/MS techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT GCMS AND RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezICPMS libraries.

This week we bring you application notes by Agilent Technologies, EST Analytical and Shimadzu!

1. Agilent Technologies: Ultrasensitive and Powerful GC/MS/MS for Analyzing Multipesticides in Black Pepper and Dried Tea

- Application note

- Full PDF for download

Pesticides play a vital role in safeguarding crops and are indispensable in most farming settings to secure high yields.1 Regulatory authorities, including the Codex Alimentarius and the European Commission mandate the monitoring and reporting of pesticide residues found in or on food product.2 The analysis of pesticides in food faces several major challenges, such as the variety of pesticide classes, the complexity of different food matrices, the effects of these matrices, and the detection of target analytes at low concentrations.3

According to the EU's SANTE/11312/2021 guidelines, black pepper and dried tea are considered among the difficult or unique commodity matrices for multiresidue pesticide analysis.4 The matrix interferences are complex and diverse, including carbohydrates, fats, piperine, terpenoids (for black pepper)5 , and caffeine (in dried tea). "For dried tea, matrix interferences include polyphenols, pigments, polysaccharides, alkaloids, free amino acids, high caffeine levels, and catechins".6

In addition to affecting the analyte signals, matrix interferences can cause the system to become contaminated more quickly. This leads to a rapid decline in the sensitivity of the analytical instrument, and necessitates frequent maintenance, significantly reducing laboratory productivity. These are the current challenges faced by laboratories when analyzing pesticides in difficult and complex matrices.

To overcome these challenges, Agilent offers a robust solution with its backflush and JetClean self-cleaning ion source technologies integrated into the high-sensitivity 7010B GC/TQ system. Backflush technology prevents high‑boiling contaminants from reaching the detector, reducing the need for frequent maintenance and extending column life.7 This ensures consistent performance and minimizes downtime, thereby enhancing laboratory productivity.

With JetClean technology, your lab can significantly increase instrument uptime, as fewer manual cleanings are needed, maximizing productivity. This technology helps maintain data quality by ensuring a clean ion source, which guarantees run-to-run reproducibility. Additionally, JetClean enhances operator convenience through automated cleaning, requiring virtually no user intervention.8 Combined with the ultrasensitivity of the 7010B GC/TQ system, these technologies provide precise and reliable analysis of pesticides in complex matrices such as black pepper and dried tea. Agilent’s comprehensive approach effectively mitigates matrix interferences, preserves instrument sensitivity, and significantly boosts overall efficiency in pesticide analysis.

This application note describes a detailed approach for the simultaneous quantification of 284 pesticides in black pepper and dried tea samples. Agilent's solution for complex matrices demonstrates the sensitivity of the 8890 GC/7010B GC/TQ and confirms its robustness when using backflush and JetClean techniques.

Experimental and chemicals

GC/TQ parameters

The 8890 GC/7010B GC/TQ systems (Figure 1) were optimized for wide calibration range performance. Equipped with an Agilent 7693A automatic liquid sampler and a 150-position tray, the GC operated in temperature‑programmed splitless injection mode with a multimode inlet. Detailed instrument parameters can be found in Table 1. Data acquisition was in dynamic MRM (dMRM) mode, enabling analysis of 284 pesticides with 1233 MRM transitions and up to 74 concurrent MRMs (see Figure 2). Retention time was synchronized with the Agilent Pesticides and Environmental Pollutants (P&EP) 4.0 MRM Database, streamlining method setup.

Conclusion

This application note describes an approach for the analysis of multipesticides in complex and distinctive matrices, including black pepper and dried tea using the Agilent 8890 GC/7010B GC/TQ. The comprehensive solution successfully addresses the challenges encountered when analyzing multipesticides in difficult matrices such as black pepper and dried tea. The high sensitivity of the 7010B GC/TQ enables the application of deep dilution methods. Additionally, the use of backflush technology combined with the Agilent JetClean self-cleaning ion source ensures system stability and robustness, enhancing the operational efficiency of testing laboratories and reducing equipment downtime during maintenance.

2. EST Analytical: Static Headspace Sampling of Volatile Organic Compounds

- Application note

- Full PDF for download

Discussion

Purge and trap sampling involves purging the VOCs out of the matrix and trapping the analytes onto an analytical trap, the trap is then desorbed to the GC/MS. This process has a number of pros and cons. On the positive side, purge and trap is more sensitive. It is also the recommended sampling technique for USEPA Methods. Furthermore, the advent of autosampling systems has simplified sample preparation. However, purge and trap does have some negatives, including active sites, worries about foaming samples, and trap degradation.

Static headspace sampling, on the other hand, is much simpler than purge and trap sampling. For this sampling technique, the sample is brought to equilibrium and a portion of the headspace is transferred to the GC/MS for separation and analysis. The simplicity of this technique is a definite pro. Moreover, this sampling process does not develop active sites, has no need for an analytical trap and the linear calibration range can be much higher than that of purge and trap sampling. Conversely, samples need to be manually prepped thus, losing their sample integrity. Additionally, the detection limits are higher for a number of compounds. Finally, some of the analytes do not partition into the headspace well enough and need method optimization.

In recent years, GC/MS systems have become much more sensitive. The advent of SIM/Scan acquisition techniques has made low level detection a much simpler proposition. This analysis will focus on the headspace sampling and analysis of over 50 volatile organic compounds.

Experimental

The sampling system used for this analysis was the EST Analytical FLEX autosampler fitted with a 2.5ml headspace syringe. An Agilent 7890 GC and 5975 MS were used for separation and analysis. The GC was configured with a Restek Rxi 624 Sil MS 30m x 250mm x 1.4µm column and a SKY 2mm x 6.5 x 78.5 splitless inlet liner. The MS was run in SIM/Scan mode. Refer to Tables 1 and 2 for the analysis and sampling parameters.

Conclusions

Static headspace sampling in conjunction with SIM/Scan acquisition proved to be a good alternative to purge and trap sampling for a number of USEPA Method 8260 compounds. The curve %RSD results showed the linearity of the curve to meet the USEPA Method 8260 requirement of 15% or better. The method detection limits of all the compounds tested also passed method requirements. Lastly, the precision and accuracy of the autosampling and analysis system was excellent, with the average precision at less than 6% RSD and the average %recovery at just over 101%.

3. Shimadzu: Aromatic Component Analysis of Gasoline According to ASTM D5580 Using the Brevis GC- 2050 Gas Chromatograph

- Application note

- Full PDF for download

Aromatics, such as toluene and xylene, are sometimes added to gasoline to improve the octane number. Measuring the levels of these aromatics is essential for quality control in gasoline production. It is also important for environmental protection, in particular, for reducing emissions of benzene, a hazardous substance, as well as for sustainable energy use that reduces the environmental impact of gasoline while maintaining its performance.

ASTM D55801) is a standard test method that uses gas chromatography to measure aromatics in gasoline. Gasoline aromatics can be separated more effectively by switching between two gas chromatography columns of different polarities and venting non-aromatic components from the system. This Application News describes using the Brevis GC2050 gas chromatograph to determine aromatics in gasoline by applying ASTM D5580.

Equipment Configuration and Analytical Conditions

The system comprises a Brevis GC-2050 gas chromatograph, an AOC-30 for sample injection, and a VB-30-S heated valve box. Aromatics were determined using two sets of Analysis Conditions that were tailored to measure different components (Table 1). Note that the timing of the flow path switching and other conditions needs to be adjusted according to the columns being used and the operating environment.

Determining Aromatics in Gasoline

A gasoline sample was prepared by adding 2 to 10 wt% aromatics and 10 wt% of an internal standard (2-hexanone) and then analyzed under Analysis Conditions A and Analysis Conditions B. Fig. 2 shows the chromatograms obtained under each set of Analysis Conditions. Despite gasoline containing large amounts of hydrocarbons, oxygenates, and other impurities, these impurities did not appear as peaks in the chromatograms, and only the aromatics added to the gasoline were detected. These results verify the utility of using flow path switching to effectively utilize the characteristics of two different columns.

Conclusion

A flow path switching valve was installed on a Brevis GC-2050 gas chromatograph to enable the determination of gasoline aromatics (benzene, toluene, ethylbenzene, p/m-xylene, oxylene, and C9+ aromatics) according to ASTM D5580.

This system can switch between different columns during analysis to determine specific aromatics from among the many compounds present in gasoline. Analysis was performed under two sets of conditions, each using different flow path switching times. This method met the requirements for linearity and reproducibility described in ASTM D5580. The timing of flow path switching can also be adjusted to allow the targeted determination of oxygenates in gasoline. The ability to perform multiple analyses on a single system means the Brevis GC-2050 offers even greater functionality as a compact gas chromatograph.