Comparison of carrier gases for the separation and quantification of mineral oil hydrocarbon (MOH) fractions using online coupled high performance liquid chromatography-gas chromatography-flame ionisation detection

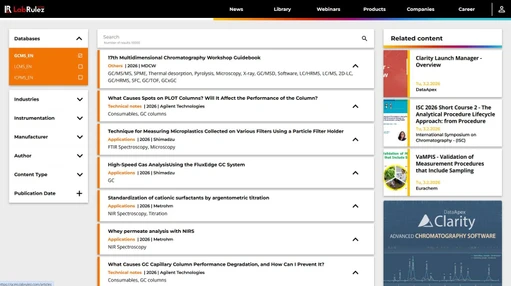

Journal of Chromatography A, Volume 1726, 2024, 464946: Fig. 4. MOH fractions of infant food formula 1 (a) and coconut oil 2 (b). Overlay of MOSH and MOAH fractions, carrier gas: nitrogen.

The study investigates the impact of different carrier gases - hydrogen, helium, and nitrogen on chromatographic performance in HPLC-GC-FID for quantifying mineral oil hydrocarbons (MOH) in food-related matrices. The goal was to determine if nitrogen, a more accessible and safer gas, could match the performance of hydrogen and helium under optimised conditions.

Results showed that nitrogen offered comparable performance in terms of linearity, quantification limits, and compound separation, despite broader peaks. Importantly, nitrogen reduced solvent peak tailing and baseline offset, supporting its use as a practical alternative for routine MOH analysis.

The original article

Comparison of carrier gases for the separation and quantification of mineral oil hydrocarbon (MOH) fractions using online coupled high performance liquid chromatography-gas chromatography-flame ionisation detection

Matthias Groschke, Roland Becker

Journal of Chromatography A, Volume 1726, 5 July 2024, 464946

https://doi.org/10.1016/j.chroma.2024.464946

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

The occurrence of mineral oil hydrocarbons (MOH) traces in food and especially in edible oils and fats has raised public concern [1]. Hydrocarbons of petrogenic origin are composed of varying ratios of saturated mineral oil hydrocarbons (MOSH) and aromatic mineral oil hydrocarbons (MOAH). The MOSH group consists of numerous mostly branched but also unbranched open-chain hydrocarbons, also named paraffins, and of cycloalkanes with varying alkylation patterns, the so-called naphthenes [2,3]. MOAH comprise aromatic hydrocarbons with one or more aromatic ring systems which are nearly exclusively alkylated [2,4]. MOH sources of relevance include depending on the food matrix printing inks released from recycled packaging, as well as lubricating oils and greases [5], [6], [7], [8], [9] either used as processing aids or present as general background contamination in the environment [10]. In cases, the determination of the respective contamination origin may pose a challenge [10]. MOH tend to accumulate in the human body [5], [6], [7] and the MOAH fraction is suspected to display toxicity [11]. Currently, there are no legal limits for MOH in foodstuff but recommendations have been issued by the European Food Safety Agency and the German Federal Institute for risk assessment (BfR) to minimise mineral oil residues in foods [6,8] and the Standing Committee on Plants, Animals, Food and Feed (SCoPAFF) of the European Commission [12]. The SCoPAFF recommendations are expected to be adopted as official regulation. MOH quantification is meanwhile done routinely using automated liquid chromatography-gas chromatography-flame ionisation detection (LC-GC-FID) procedures including integrated sample preparation for the epoxidation of interfering natural olefins and aluminium oxide treatment for the removal of biogenic n-alkanes, enabling high sample-throughput at reduced contamination risk [13]. Standardisation and improvement of sample preparation are currently ongoing [[14], [15], [16], [17]].

MOSH and MOAH are typically separated by LC on a normal phase and then either transferred consecutively onto the same short (10 –15 m) GC column with a thin film (0.1–0.25 µm) via on-column-type interfacing [2,10,18,19,20] or separately onto two similar column configurations. Accordingly, either one or two flame ionisation detectors are employed. Though a number of alternative LC-GC interfacing concepts involving programmed temperature vaporising (PTV) have been described [21], commercial laboratories apply exclusively the standardised procedure according to EN 16995 [14] and ISO/DIS 20122 [15]. While some workers in the field use hydrogen as carrier gas [13,17] as suggested by EN 16995 [14] and that is considered superior due to the higher gas velocity in the precolumn [13], others, including some routine laboratories use helium [10,16,22], especially if FID is used in parallel to MS detection [23]. Instead, nitrogen is generally considered as a poor carrier gas. According to the van Deemter equation nitrogen has a low optimum of linear velocity which tends to increase the run time for sufficient separations and apparently has never been considered as carrier gas for LC-GC-FID analysis of MOSH/MOAH traces in the literature. Cost benefit considerations triggered the quest for a investigation of nitrogen as alternative to the usual carrier gases for the LC-GC-FID quantification of MOSH and MOAH with sufficient accuracy and sensitivity. For this purpose, neat mineral oils, (highly refined mineral oil, gear oil, engine oil with significant amounts of MOAH, two coconut oils and two infant formula samples each displaying MOSH/MOAH trace concentrations of practical relevance were employed. GC parameters were optimised for each carrier gas and the separation and quantification characteristics were compared and are discussed in regard to practical implications.

2. Experimental

2.4. Online coupled high performance liquid chromatography-gas chromatography-flame ionisation detection (LC-GC-FID)

LC-GC-FID experiments were performed on a CHRONECT workstation MOSH/MOAH from Axel Semrau (Sprockhövel, Germany) composed of a 1100 HPLC system (binary pump and variable wavelength detector from Agilent Technologies, Waldbronn, Germany), an Agilent 7890A gas chromatograph (GC) with a flame ionisation detector (FID) and a robotics platform based on a Combi PAL autosampler (CTC Analytics AG, Zwingen, Switzerland). Three rotatory switching valves (VICI AG International, Schenkon, Switzerland) were used to guide the eluent from the HPLC into the GC. The GC was equipped with one on-column interface and one solvent vapor exit. A range of 5 μL to 100 μL of the prepared samples were injected onto an Allure Silica HPLC column (250 mm x 2.1 mm, 5 μm, 60 Å, Restek, Bellefonte, PA, USA) without additional column temperature control. The mobile phase consisted of n-hexane and dichloromethane. Starting at 100 % n-hexane with 300 μL/min, the mobile phase was changed to 65 % n-hexane 1.0 min after injection and held for additional 5.0 min. MOSH was eluted between 2.0 – 3.5 min (450 μL). After elution of the MOAH fraction (4.3 – 5.8 min, 450 μL), the silica gel HPLC column was backflushed with dichloromethane at 500 μL/min for 9 min. Afterwards, the column was reconditioned with n-hexane at 500 μL/min for 15 min. The MOAH elution window was verified by UV detection at 230 nm. 1,3,5-tri‑tert-butylbenzene (TBB) and perylene (Per) marked the starting- and endpoint of this window. LC-GC transfer was done by the retention gap technique and partially concurrent solvent evaporation [18]. An uncoated precolumn (deactivated stainless steel, 10 m x 0.53 mm, Restek, Germany) was followed by a steel T-piece union (modified butt-to-butt connector, Trajan Scientific and Medical, Ringwood, Australia) connecting to the solvent vapor exit and a separation column coated with a 100 % dimethyl polysiloxane film (MXT-1, Siltek-treated stainless steel, 15 m x 0.25 mm x 0.25 μm, Restek, Bellefonte, PA, USA). From HPLC, the MOSH and MOAH fractions were transferred to GC at an oven temperature of 60 °C. The solvent vapor exit was opened 0.5 min prior to elution of each fraction and was closed 0.3 min after the fraction was transferred. The oven temperature program and gas flow were adjusted for the respective carrier gas as reported in the discussion below. The FID base temperature was set to 380 °C. The carrier gas flows were subject to optimisation as given in Table 1. The FID gas flows for air, hydrogen, and nitrogen were set to 300, 30, and 30 mL/min, respectively. Data processing was performed with Clarity 8.5 (DataApex, Prague, Czech Republic). Quantitation by use of internal standards was based on bicyclohexyl (cyclohexyl cyclohexane, Cycy) for MOSH and 2-methyl naphthalene (2-MN) for MOAH, and TBB for MOAH in case of epoxidated samples.

3. Results and discussion

3.2. Comparison of carrier gases using neat mineral oils

The selected mineral oil samples were chosen to cover different boiling ranges, hump shapes and MOSH to MOAH ratios. Shell SN 500 is a high refined mineral oil and used as a quality control sample by the JRC [2]. Shell Omala 68 and Omala 220 are gear oils with wide boiling range of mineral oil hydrocarbons and representatively for common contaminations in tropical oils. Shell Ondina X430 as a medical white oil is free of MOAH and useful for LoQ determinations.

Fig. 3 shows the chromatograms obtained with the three carrier gases after injection of 100 ng medical white oil Shell Odina that consists of 100 % MOSH. It is again seen that nitrogen is most favourable in regard for tailing and that the detector response is largely unaffected by the carrier gas. Thus, the requirement to reach a LoQ of 1 mg/kg – the detectability of 50 – 100 ng MOSH - [3,26] is therefore easily met with all carrier gases. The signal to noise ratio is sufficient to allow quantifying even lower amounts. It should also be noted that nitrogen does not display a significant hump widening compared to the other two carrier gases. In fact, the humps are not different among carrier gases.

Journal of Chromatography A, Volume 1726, 2024, 464946: Fig. 3. Injection of 50 ng medical white oil (=Shell Odina X430, pure MOSH), overlay of chromatograms obtained with the three carrier gases. Green = N2, Blue = He, Red = H2.

Journal of Chromatography A, Volume 1726, 2024, 464946: Fig. 3. Injection of 50 ng medical white oil (=Shell Odina X430, pure MOSH), overlay of chromatograms obtained with the three carrier gases. Green = N2, Blue = He, Red = H2.

3.3. Comparison of carrier gases for vegetable oils and infant formula analyses

Fig. 4 depicts by example the overlaid MOSH and MOAH chromatograms obtained from a coconut oil and an infant formula using nitrogen as carrier gas. The standard compounds and the MOSH and MOAH humps are all well separated and elute within the required time frame of 30 min. Supplementary Fig. S5 shows for comparison the overlaid MOSH and MOAH chromatograms obtained from coconut oil 2 with the three carrier gases. Again, the chromatograms are nearly indistinguishable, especially regarding the standard compounds and the MOSH and MOAH fraction humps. Conspicuously, nitrogen leads to the least solvent tailing and allows for detection of highly volatile compounds which extend the information on MOH contamination obtainable by this analytical approach. Table 5 comprises all MOSH and MOAH quantification data obtained. Obviously, the results obtained with the different carrier gases are not distinguishable against an assumed uncertainty range of ± 10 % (see discussion of Table 3).

Journal of Chromatography A, Volume 1726, 2024, 464946: Fig. 4. MOH fractions of infant food formula 1 (a) and coconut oil 2 (b). Overlay of MOSH and MOAH fractions, carrier gas: nitrogen.

Journal of Chromatography A, Volume 1726, 2024, 464946: Fig. 4. MOH fractions of infant food formula 1 (a) and coconut oil 2 (b). Overlay of MOSH and MOAH fractions, carrier gas: nitrogen.

4. Conclusion

After optimisation of chromatographic settings nitrogen can be considered as suitable carrier for the determination of mineral oil contaminants in food related matrices by LC-GC hyphenation. Changing to nitrogen allows retaining the GC runtime while still sufficient peak resolutions and appropriate peak shapes are obtained. Recoveries, repeatabilities, LoQs, linear ranges and carry over were equivalent with all carrier gases. This and the lower solvent band tailing and baseline offset might well encourage the use of nitrogen as alternative carrier gas in cases where this may economically favourable.